Landfill examples are examples of sites for disposing of non-recycled waste, including household waste (plastics, packaging, glass), commercial, building and demolition waste, and industrial waste. Food trash, paper, cardboard, power plant ash, contaminated soils, and plastic bottles are a few examples of things that can be found in landfills. Some landfills, such as bioreactor landfills, which treat biological waste, or coal combustion residual landfills, which manage ash, are specifically constructed to handle particular waste types.

Read on to find out more fascinating facts about our example landfills!

Landfill Examples – Key Takeaways

- Modern sanitary landfills incorporate essential engineered systems, including liner systems, leachate collection networks, and gas management systems to protect the environment while managing waste effectively.

- Bioreactor landfills accelerate waste decomposition through controlled moisture addition, resulting in increased gas production for energy generation and extended landfill life.

- Specialised secure landfills for hazardous waste feature enhanced safety measures, including double-liner systems and specialised containment technologies.

- Well-designed landfill cells utilise strategic daily cover materials, proper compaction techniques, and calculated slopes to maximise capacity while maintaining stability.

- Advanced monitoring technologies, including groundwater well networks and gas migration detection systems, provide crucial data for proactive environmental protection.

Landfill examples of effective waste management start with proper landfill design and operation. While many waste professionals focus on collection and transport, the final destination—the landfill itself—determines the long-term environmental and economic success of any waste management system.

Our example andfills have evolved dramatically from the open dumps of the past into sophisticated engineered systems that protect groundwater, capture greenhouse gases, and even generate renewable energy. Today's waste management professionals must understand these advanced designs to meet increasingly strict regulations while maintaining operational efficiency.

“Landfills” from sswm.info and used with no modifications.

Modern Landfill Designs That Actually Work

Modern landfills represent complex engineering achievements that balance waste containment, environmental protection, and operational efficiency. These facilities must function effectively for decades while adapting to changing waste streams, weather conditions, and regulatory requirements. The most successful designs incorporate redundant safety features, flexible operational components, and forward-thinking closure plans.

When designed properly, today's landfills minimise environmental impacts through multiple containment layers, active management systems, and continuous monitoring. They also create opportunities for the beneficial use of otherwise wasted resources, particularly landfill gas that can be converted to energy. Waste360, an industry-leading resource for waste management professionals, offers comprehensive guides on implementing these designs to maximise both environmental protection and operational efficiency.

For example, successful landfill designs share several critical characteristics that support their long-term performance:

- Comprehensive environmental control systems (leachate management, gas collection, stormwater controls)

- Carefully engineered containment structures with redundant safety features

- Phased development plans that maximise airspace while minimising operational footprints

- Flexibility to adapt to changing waste compositions and volumes

- Integrated monitoring systems that provide early warning of potential issues

Sanitary Landfilling Practice – Source: Handbook of Environmental Engineering, vol 24. Springer, Cham. https://doi.org/10.1007/978-3-030-89336-1_8

Sanitary Landfills: The Foundation of Modern Waste Management

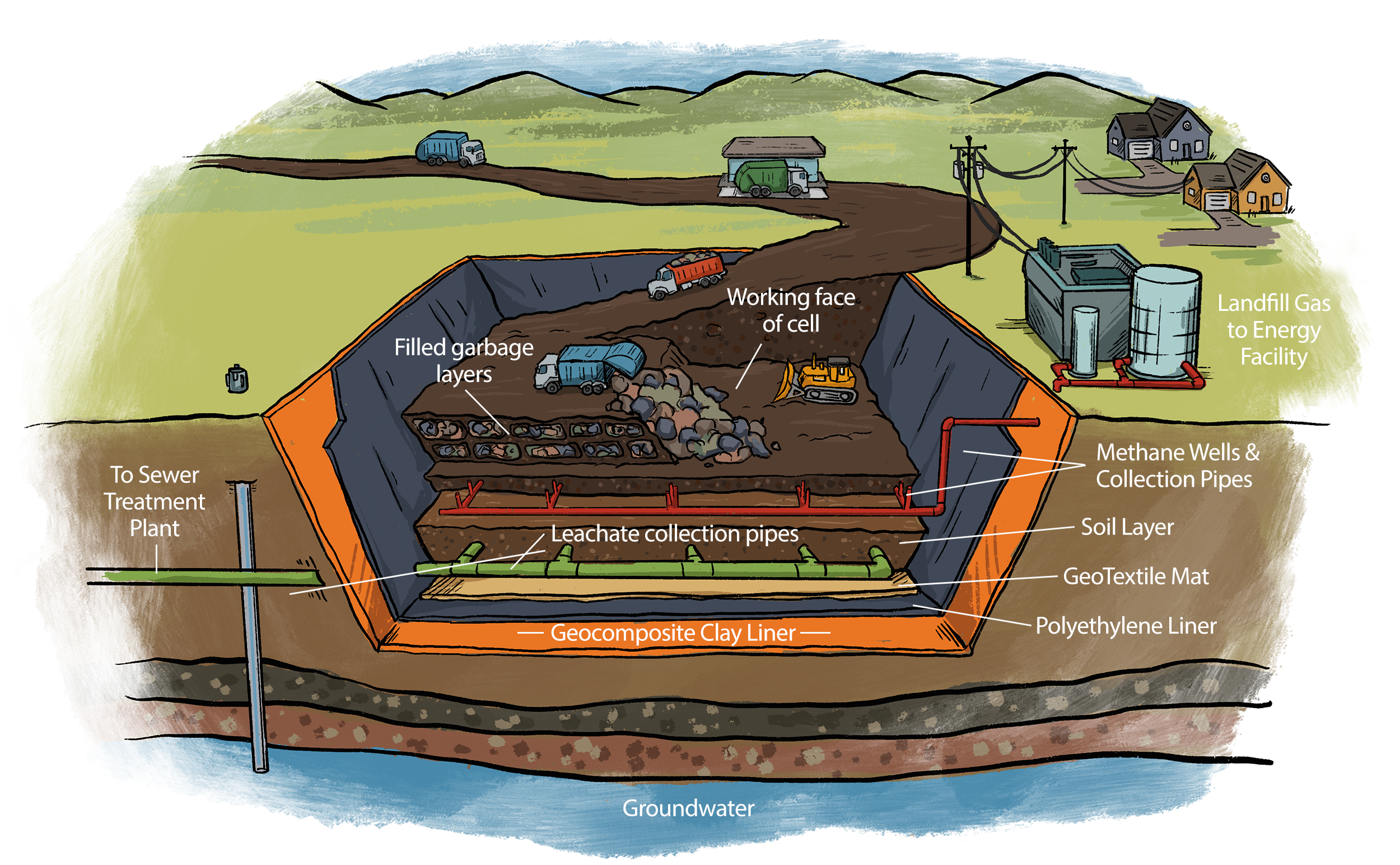

Sanitary landfills represent the baseline standard for modern waste disposal facilities. Unlike the unlined dumps of previous generations, these engineered facilities incorporate multiple protective features to isolate waste from the surrounding environment. The sanitary landfill concept emphasises the systematic placement and daily covering of waste to reduce vectors (rats, flies), minimise odours, and prevent windblown debris.

Essential Components of a Sanitary Landfill

Every properly designed sanitary landfill incorporates several critical components that work together as an integrated system. The foundation begins with careful site selection that considers geology, hydrogeology, and proximity to sensitive receptors. Beyond site selection, the physical infrastructure must meet both regulatory requirements and operational needs while providing multiple layers of environmental protection.

The essential components that define a modern sanitary landfill include:

- Composite liner system (typically clay and geomembrane combinations)

- Leachate collection and removal system

- Landfill gas management system

- Stormwater management controls

- Daily, intermediate, and final cover systems

- Environmental monitoring networks

“A typical composite liner system in …” from www.researchgate.net and used with no modifications.

Liner Systems That Prevent Groundwater Contamination

The liner system serves as the primary defence against groundwater contamination and forms the foundation of any successful landfill. Modern liner designs typically employ a composite approach that combines the complementary properties of different materials. The standard composite liner includes a geomembrane (typically high-density polyethylene) overlying a compacted clay layer, creating redundant protection against leachate migration.

Advances in geosynthetic materials have dramatically improved liner performance while reducing construction challenges. Modern liner systems often incorporate additional components such as geosynthetic clay liners (GCLs), which provide consistent hydraulic barriers even in areas with poor native clay resources. Drainage layers, typically constructed of granular material or geocomposite drainage nets, direct leachate to collection systems while reducing hydraulic head on the liner.

Leachate Collection Networks: Keeping Toxic Liquids Contained

Leachate—the liquid that forms as water percolates through waste—represents one of the most significant environmental threats from landfills. Effective leachate management begins with a properly designed collection system that removes this liquid from the waste mass before it can accumulate and place pressure on the liner system. The collection network typically consists of perforated pipes embedded in a drainage layer above the liner, sloped to direct flow to sumps for removal.

- Perforated collection pipes sized to handle peak flows

- Drainage media with sufficient permeability (gravel or geocomposite)

- Filter layers that prevent clogging from fine particles

- Cleanout access points for maintenance

- Pumping systems that can adapt to changing leachate generation rates

Once collected, leachate requires appropriate treatment before discharge. Treatment approaches vary based on leachate characteristics and local requirements, ranging from on-site biological treatment to off-site processing at wastewater treatment plants. Some facilities employ evaporation systems or leachate recirculation (in bioreactor applications) to reduce treatment volumes.

“Typical Landfill Leachate Collection …” from www.researchgate.net and used with no modifications.

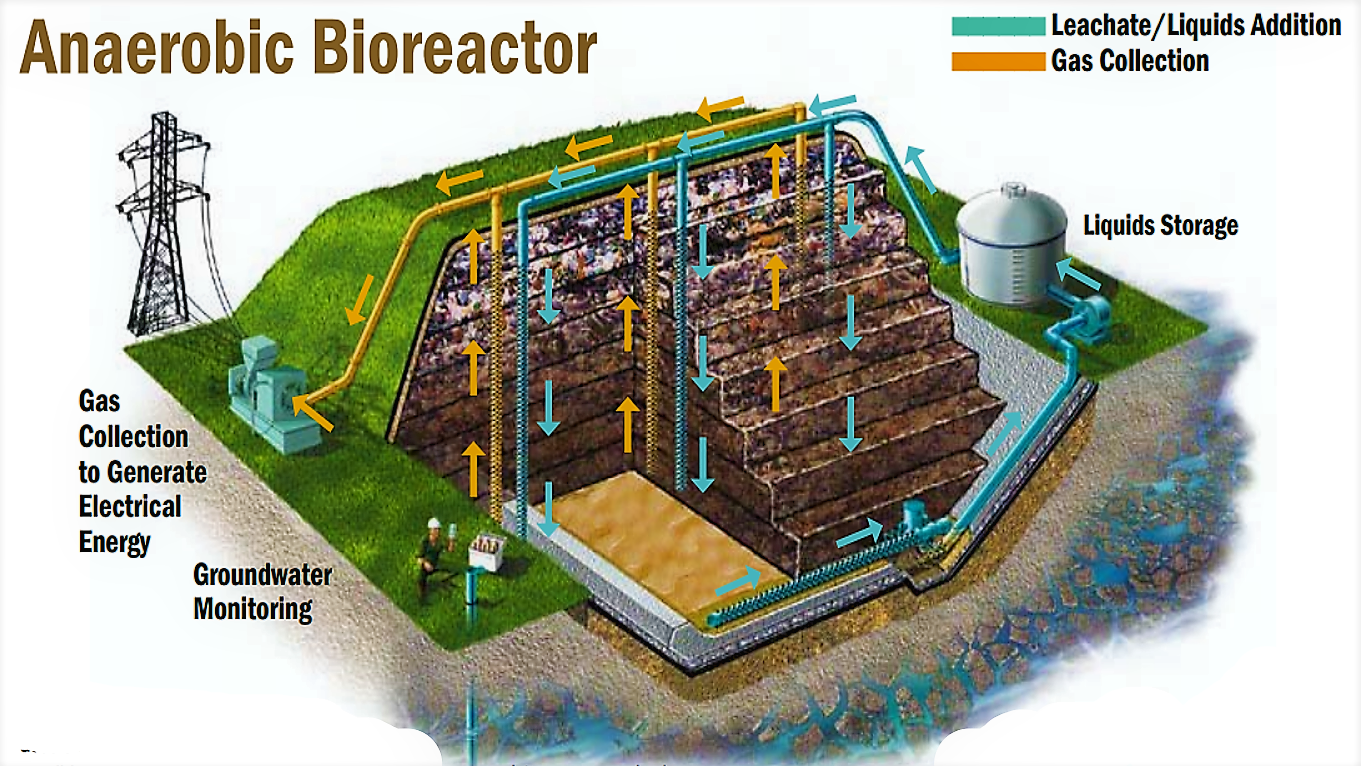

Bioreactor Landfills: Turning Trash into Energy

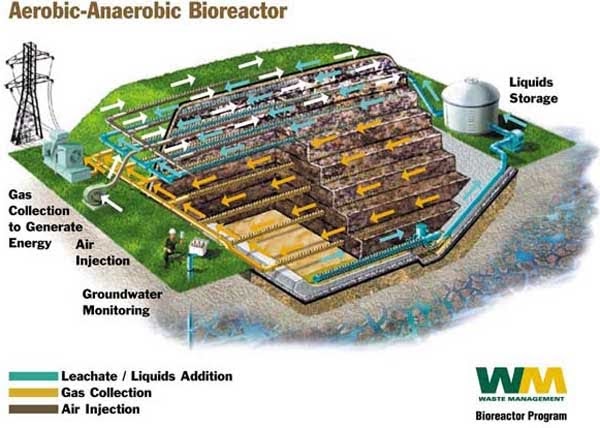

Bioreactor landfills represent an evolution beyond traditional sanitary landfills by actively managing the decomposition process rather than simply containing waste. By controlling moisture content within the waste mass, bioreactor landfills accelerate biodegradation, which produces several operational advantages, including increased gas generation, reduced leachate treatment requirements, and accelerated settlement that increases available airspace. For more information on the benefits and drawbacks of sanitary landfill sites, explore our detailed guide.

The controlled addition of moisture—typically through leachate recirculation—transforms a conventional “dry tomb” landfill into a biological reactor. This approach harnesses and optimises the natural decomposition processes that would otherwise occur slowly over decades or centuries. The EPA has recognised bioreactor technology as a beneficial innovation in landfill design that can reduce environmental impacts while improving operational efficiency.

Implementing bioreactor technology requires careful design modifications to standard landfill components, including enhanced gas collection systems, reinforced leachate recirculation infrastructure, and more sophisticated monitoring networks. These facilities typically require specific regulatory approval as they intentionally deviate from traditional dry-tomb approaches.

“Bioreactor Landfills in the United …” from www.geoengineer.org and used with no modifications.

How Moisture Control Accelerates Waste Decomposition

Moisture serves as the critical catalyst in bioreactor operations, providing the medium necessary for microbial activity that drives waste decomposition. Traditional landfills often maintain relatively dry conditions that limit bacterial activity, essentially mummifying waste rather than decomposing it. Bioreactors maintain optimal moisture levels—typically between 40-60% by weight—to create ideal conditions for methanogenic bacteria.

Moisture addition systems vary in design but commonly include horizontal infiltration galleries, vertical injection wells, and surface application methods. The most effective approach often involves a combination of these technologies to ensure even moisture distribution throughout the waste mass. Operators must carefully monitor moisture levels to prevent oversaturation that could lead to increased leachate production or slope stability issues.

Gas Collection Systems That Generate Revenue

The accelerated decomposition in bioreactor landfills produces significantly more landfill gas (LFG) in a shorter timeframe than conventional facilities. This concentrated gas production creates opportunities for beneficial use projects that convert this methane-rich gas into energy. Modern gas collection systems typically consist of networks of vertical extraction wells, horizontal collectors, and header pipes that create negative pressure to draw gas from the waste mass.

Advanced gas collection designs now incorporate automated wellfield monitoring and control systems that optimise collection efficiency while minimising air intrusion. These systems allow operators to fine-tune vacuum levels at individual wells, adjusting to changing gas production rates and waste characteristics. The collected gas can be processed for direct use as medium-BTU fuel, upgraded to pipeline-quality renewable natural gas, or used to generate electricity through engines, turbines, or fuel cells.

- Vertical extraction wells are typically spaced 100-200 feet apart

- Horizontal collectors installed during active filling

- Automated wellhead monitoring and control systems

- Condensate management components to handle moisture

- Energy recovery facilities sized to match gas production curves

![]()

“RCR | Landfill Gas” from rcrcommodities.com and used with no modifications.

Operational Challenges and Solutions

Despite their benefits, bioreactor landfills present unique operational challenges that require specialised management approaches. The increased moisture content can create temporary slope stability concerns, particularly during initial operational phases when waste is less consolidated. Engineers address these issues through reinforced perimeter berms, staged filling plans, and careful monitoring of pore pressures within the waste mass.

Operators must also manage increased odour potential during active recirculation activities. Solutions include conducting recirculation during favourable atmospheric conditions, using focused odour neutralisation systems during critical operations, and maintaining robust gas collection efficiency to capture odorous compounds before they can escape. Temperature management presents another challenge, as accelerated decomposition generates significant heat that must be monitored to prevent internal fires.

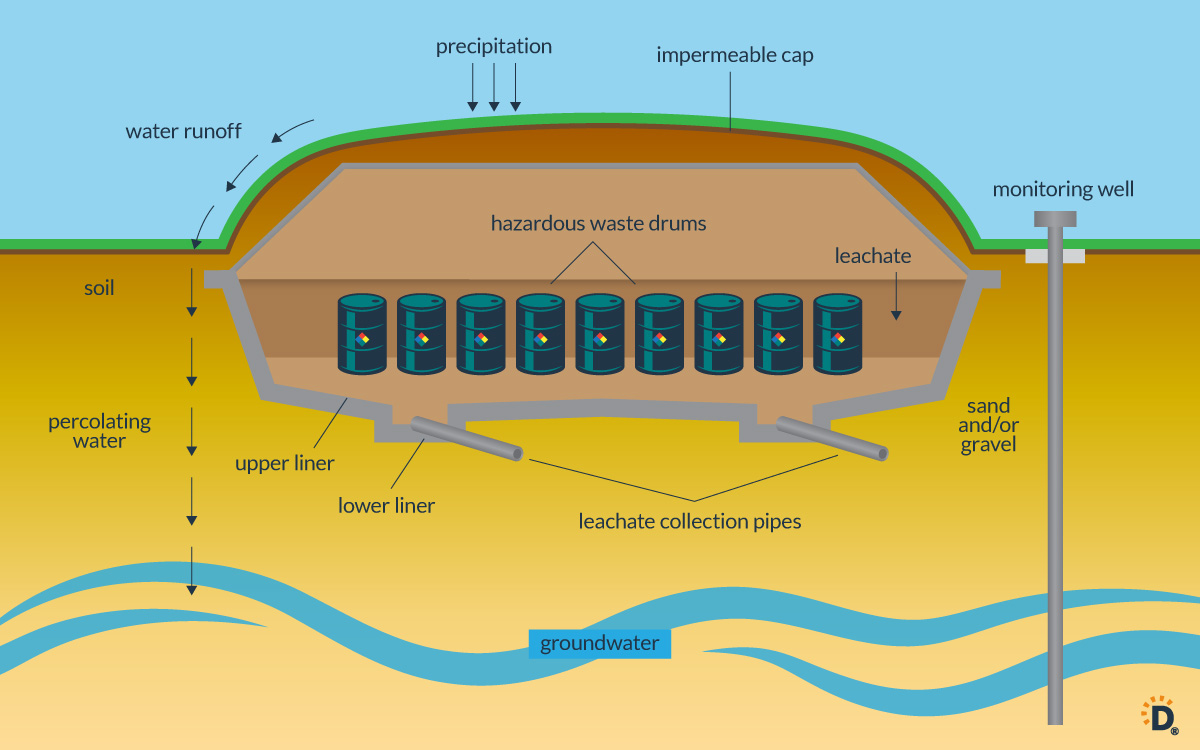

Secure Landfills for Hazardous Waste Management

Hazardous waste requires specialised containment systems beyond those used in municipal solid waste landfills. Secure landfills designed for these materials incorporate additional protective features, monitoring systems, and operational controls to ensure long-term isolation of potentially dangerous substances. These facilities must comply with stringent design and performance standards under Subtitle C of the Resource Conservation and Recovery Act (RCRA).

Double-Liner Systems and Enhanced Safety Features

The foundation of secure landfill design begins with a double-liner system that provides redundant protection against contaminant migration. The primary (upper) liner typically consists of a high-density polyethylene (HDPE) geomembrane overlying a compacted clay layer or geosynthetic clay liner. Below this, a leak detection system monitors for any failure in the primary liner, while a secondary composite liner provides backup containment.

“Double Composite Liner Landfill …” from www.researchgate.net and used with no modifications.

Between the primary and secondary liners, an engineered leak detection system consisting of a drainage layer and collection pipes allows operators to monitor for any breaches in the primary liner. This system not only detects leaks but also removes any leachate that might penetrate the upper liner, preventing it from reaching the secondary liner.

Monitoring data from these systems provides early warning of potential liner integrity issues before environmental impacts can occur.

Secure Landfill Liner Components (Top to Bottom)

Primary Composite Liner: 60-mil HDPE geomembrane over 3 feet compacted clay (k≤1×10^-7 cm/sec)

Leak Detection System: Geocomposite drainage layer with collection pipes

Secondary Composite Liner: 60-mil HDPE geomembrane over 3 feet compacted clay (k≤1×10^-7 cm/sec)

Vadose Zone Monitoring System: Sensors beneath landfill to detect any releases

“Davis Landfill – Wasatch Integrated …” from www.wasatchintegrated.gov and used with no modifications.

Specialised Handling Requirements

Beyond enhanced containment systems, secure landfills implement specialised waste handling procedures to address the unique risks associated with hazardous materials. All incoming waste undergoes rigorous verification testing to confirm it matches profile documentation and meets acceptance criteria. Many facilities employ dedicated unloading areas with containment features to manage potential spills during the disposal process.

Waste placement strategies in secure landfills often include segregation of incompatible wastes, specialised neutralisation of reactive materials, and solidification processes for liquid wastes. Operators maintain detailed waste placement records documenting the exact location of specific waste types within the landfill cells. These records prove invaluable for future reference should any remediation become necessary or if the facility transitions to post-closure status.

“Where Does Hazardous Waste Go …” from www.dumpsters.com and used with no modifications.

An Example of the Anatomy of a Well-Designed Landfill Cell

The individual cell represents the fundamental building block of modern landfill design. Each cell is constructed as a discrete unit with its own liner system, leachate collection network, and perimeter berms. This approach allows for phased development, limiting the exposed liner area and providing operational flexibility as the facility expands over its lifetime.

Cell dimensions typically reflect a balance between operational efficiency, construction economics, and stormwater management considerations. The optimal footprint varies by site but generally ranges from 5-15 acres—large enough to provide sufficient operational space but small enough to manage stormwater effectively during construction and filling. Depth configurations depend on site-specific factors, including groundwater separation requirements, available airspace, and stability considerations.

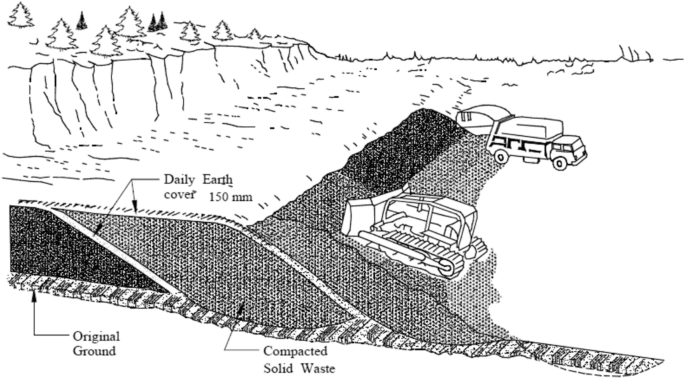

Daily Cover Materials and Their Functions

Daily cover plays a crucial role in landfill operations, providing temporary containment between active filling periods. Traditional soil cover (typically 6-12 inches applied daily) controls vectors, minimises odours, prevents blowing litter, reduces fire risk, and limits infiltration. However, soil cover consumes valuable airspace that could otherwise hold revenue-generating waste.

Alternative daily cover (ADC) materials have gained popularity as operators seek to maximise airspace utilisation. These alternatives include spray-applied foams, geosynthetic tarps, green waste, auto shredder residue, and various processed industrial byproducts. Regulatory acceptance of these materials varies by jurisdiction, but properly selected ADCs can provide equivalent environmental protection while preserving landfill capacity.

Daily Cover Materials and Their Functions

Daily cover plays a crucial role in landfill operations, providing temporary containment between active filling periods. Traditional soil cover (typically 6-12 inches applied daily) controls vectors, minimises odours, prevents blowing litter, reduces fire risk, and limits infiltration. However, soil cover consumes valuable airspace that could otherwise hold revenue-generating waste.

Alternative daily cover (ADC) materials have gained popularity as operators seek to maximise airspace utilisation. These alternatives include spray-applied foams, geosynthetic tarps, green waste, auto shredder residue, and various processed industrial byproducts. Regulatory acceptance of these materials varies by jurisdiction, but properly selected ADCs can provide equivalent environmental protection while preserving landfill capacity.

“Schematic view of a daily cover. Soil …” from www.researchgate.net and used with no modifications.

Cell Construction Techniques for Maximum Capacity

Strategic cell construction directly impacts a landfill's operational efficiency and total capacity. The lift sequence—how waste is placed within each cell—follows carefully designed plans that optimise compaction while maintaining proper slopes. Most facilities employ the area method where waste is spread in thin layers (12-24 inches) and compacted before the next layer is added, building upward in a series of lifts until reaching design elevation.

Compaction represents perhaps the most critical operational factor affecting capacity utilisation. High-quality compaction equipment operated by skilled personnel can achieve waste densities of 1,200-1,500 pounds per cubic yard, significantly higher than poorly compacted facilities. This increased density translates directly to extended site life and improved revenue potential without expanding the facility footprint.

Sloping and Terracing Methods for Stability

Proper slope design balances stability requirements with airspace maximisation goals. While steeper slopes create more capacity, they increase the risk of failures that could compromise environmental systems or endanger personnel. Modern designs typically incorporate terraced configurations with intermediate benches that interrupt long continuous slopes, improving both stability and access for maintenance activities.

Regulatory standards generally limit exterior slopes to 3:1 (horizontal: vertical) or flatter, though interior slopes between cells may be designed somewhat steeper. The terraced approach creates multiple slope segments separated by horizontal benches (typically 15-30 feet wide) that serve as access roads, utility corridors, and stormwater control features. This configuration also facilitates staged final closure, allowing portions of the landfill to receive final cover while other areas remain active.

“Optimizing cover soil usage …” from www.wastetodaymagazine.com and used with no modifications.

Strategic Phasing for Optimal Landfill Life

Thoughtful phasing plans divide the overall landfill footprint into logical development sequences that balance construction costs against operational needs. Each phase includes sufficient capacity to justify the construction investment while limiting the active area requiring daily cover and stormwater management. This approach minimises initial capital requirements while deferring major expenditures until they're offset by disposal revenue.

Effective phasing plans consider seasonal construction limitations, projected waste flows, and the economic life of liner system components. They also incorporate flexibility to adapt to changing waste volumes or regulatory requirements that might emerge during the facility's operational lifetime. The most successful plans integrate cell development with the progressive installation of permanent infrastructure including access roads, scales, gas collection systems, and leachate management components.

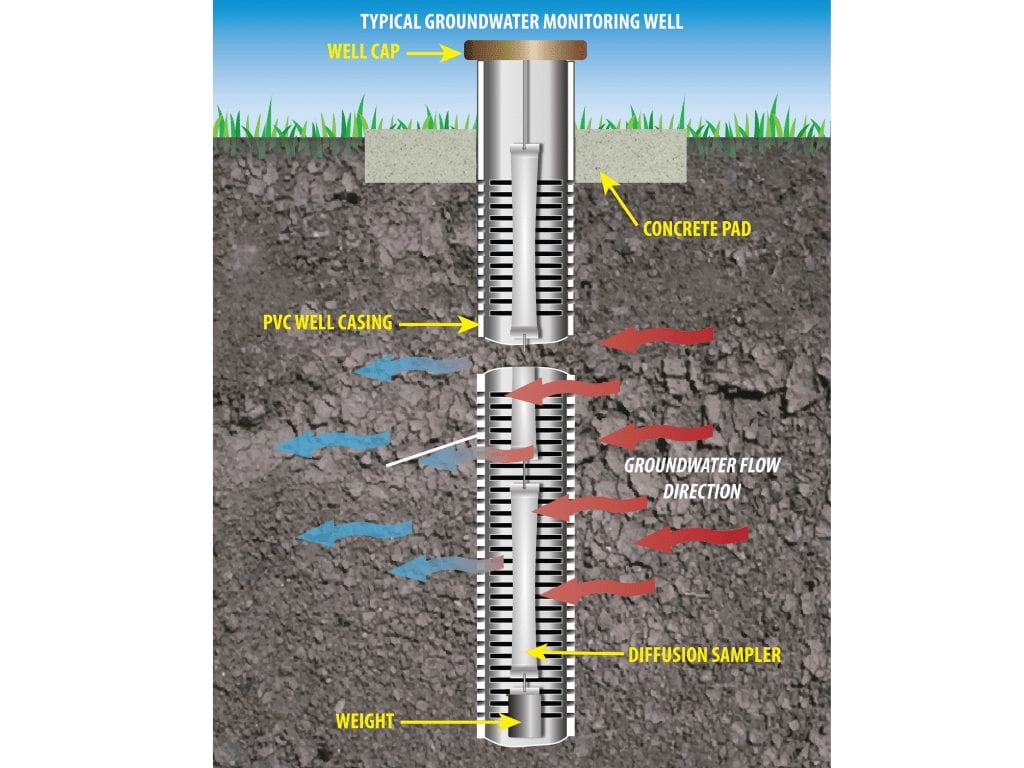

Advanced Monitoring Systems in Modern Landfills

Environmental monitoring represents a cornerstone of modern landfill management, providing crucial data on system performance and early warning of potential issues. These monitoring networks extend far beyond minimal regulatory compliance, offering operators actionable intelligence that drives operational decisions and demonstrates environmental responsibility to regulators and communities alike.

Today's monitoring systems leverage advances in sensor technology, data transmission, and analytical software to provide comprehensive, real-time information on critical landfill functions. These integrated systems allow operators to transition from reactive to proactive management approaches, addressing potential problems before they develop into regulatory violations or environmental releases.

Groundwater Monitoring Well Networks

Comprehensive groundwater monitoring networks form the backbone of environmental protection systems at modern landfills. These networks typically include upgradient wells to establish background water quality conditions and multiple downgradient wells positioned to detect potential impacts from the facility. Well placement reflects site-specific hydrogeologic conditions including groundwater flow direction, depth to aquifer, and the presence of preferential pathways.

Beyond basic placement, modern monitoring systems employ nested well designs that sample from different depths within the aquifer system, providing three-dimensional data on groundwater conditions. Sampling frequencies have evolved beyond quarterly programs to include continuous monitoring sensors for critical parameters such as water levels, conductivity, and temperature. These continuous systems can trigger automated alerts when parameters exceed predetermined thresholds, allowing for immediate investigation. For more information on landfill operations, you can explore the RAMP method of waste disposal.

“Monitoring Wells Installation | Monitor …” from allamericanenviro.com and used with no modifications.

Gas Migration Detection Technology

Landfill gas migration presents both safety and environmental concerns that require vigilant monitoring. Traditional approaches relied on periodic bar-hole punch testing along property boundaries, but modern facilities employ permanent monitoring probes with dedicated sampling ports at multiple depths. These probes typically monitor methane concentrations, pressure, and sometimes carbon dioxide levels to assess both the presence and movement of landfill gas.

Advanced gas monitoring now incorporates continuous monitoring stations that transmit data to central management systems, triggering alerts when gas levels approach regulatory thresholds. Some facilities supplement these fixed monitoring points with periodic surface emission scans using infrared cameras or laser-based detection systems that can identify discrete emission points across the landfill surface. This comprehensive approach ensures both perimeter compliance and effective gas collection throughout the waste mass.

Settlement Monitoring for Long-term Stability

Waste settlement directly impacts both operational efficiency and post-closure maintenance requirements. Modern landfills implement systematic settlement monitoring programs that track vertical movement across the facility using survey monuments, inclinometers, and in some cases, remote sensing technologies. This data guides operational decisions regarding waste placement, final grading plans, and the timing of final cover installation.

Differential settlement poses particular challenges for environmental control systems, potentially damaging gas collection pipes, leachate collection lines, or final cover components. Advanced monitoring programs include threshold values that trigger investigative actions when settlement rates or patterns deviate from expected values. This proactive approach allows operators to implement remedial measures before environmental systems are compromised. For more insights on landfill design, visit this landfill design guide.

Case Study: The Puente Hills Landfill Transformation

The Puente Hills Landfill in Los Angeles County exemplifies how innovative design and operational strategies can transform waste management challenges into community assets. Once one of the largest landfills in the United States, receiving up to 13,200 tons of waste daily, Puente Hills operated for over 56 years before closing in 2013. Its transformation demonstrates the full lifecycle of modern landfill development from active operation through closure and beneficial reuse.

“Puente Hills Landfill – Wikipedia” from en.wikipedia.org and used with no modifications.

This 1,365-acre facility incorporated numerous design innovations during its operational life, particularly in gas management and energy recovery. Its closure plan demonstrates how thoughtful post-closure design can convert former disposal sites into valuable community resources while maintaining environmental protection systems.

Puente Hills Landfill By The Numbers

Years of Operation: 1957-2013

Total Waste In Place: 130+ million tons

Maximum Height: 500 feet

Gas-to-Energy Capacity: 50 megawatts

Post-Closure Park Acreage: 142 acres

From Environmental Problem to Energy Producer

Puente Hills pioneered large-scale landfill gas-to-energy development with its gas recovery facility generating enough electricity to power approximately 70,000 homes. The system incorporates over 500 extraction wells connected via a network of collection pipes that feed a central power plant. This facility demonstrated that landfills could serve as significant renewable energy sources while simultaneously reducing greenhouse gas emissions and generating revenue to offset operational costs. For more information on the benefits and drawbacks of landfill sites, visit this guide.

“Puente Hills Landfill Gas-to-Energy …” from www.lacsd.org and used with no modifications.

Recreation Area Development After Closure

The post-closure transformation of Puente Hills into a regional park exemplifies modern end-use planning. The Puente Hills Landfill Park Master Plan integrates recreational facilities, habitat restoration areas, and interpretive features that educate visitors about waste management and environmental protection. The design incorporates specialised engineering features to accommodate ongoing settlement while creating usable public spaces, including hiking trails, scenic overlooks, and picnic areas.

This conversion required careful coordination between environmental control systems and recreational features. Gas collection infrastructure, leachate management components, and monitoring networks continue operating beneath the park landscape, made accessible through strategically placed maintenance corridors. The project demonstrates how thoughtful integration of technical requirements with community needs can create valuable public assets from former disposal facilities.

“File: Puente Hills Gas-To-Energy …” from commons.wikimedia.org and used with no modifications.

Innovative International Landfill Designs

While U.S. landfill regulations establish strict baseline requirements, international designs often incorporate innovative approaches that address specific regional challenges or regulatory frameworks. These international perspectives offer valuable insights that can inform domestic practices, particularly as waste compositions evolve and climate considerations become increasingly important.

Different regions have developed specialised approaches based on local conditions, available materials, and cultural priorities. By examining these diverse strategies, waste management professionals can identify adaptable innovations that might benefit their own operations while maintaining compliance with local regulations.

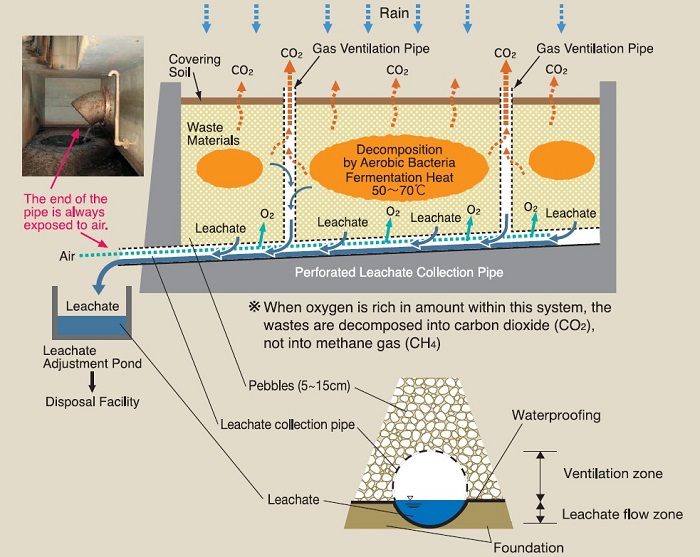

Japan's Semi-Aerobic Fukuoka Method

Japan's Fukuoka Method represents a fundamentally different approach to landfill design, incorporating passive aeration to promote aerobic decomposition rather than the anaerobic processes typical in conventional designs. This semi-aerobic approach uses natural convection through strategically placed pipes to draw air into the waste mass, accelerating decomposition while reducing methane generation and improving leachate quality.

The design features a perforated leachate collection pipe network that serves the dual purpose of draining leachate and introducing air into the waste mass. This simple but effective approach has gained popularity throughout Asia for its relatively low implementation cost and reduced environmental impact, particularly in regions where methane capture is not economically feasible.

“semi-aerobic landfill structure …” from www.city.fukuoka.lg.jp and used with no modifications.

Germany's MBT (Mechanical-Biological Treatment) Approach

Germany has pioneered the integration of pre-treatment technologies with landfill disposal through its widespread adoption of Mechanical-Biological Treatment (MBT) systems. These facilities process mixed waste through sorting equipment that recovers recyclables and separates organic fractions for biological treatment before landfilling. The resulting stabilised material produces significantly less gas and leachate than untreated waste, reducing the environmental footprint of disposal operations. For further insights, explore the food waste processing technologies that complement these systems.

This approach fundamentally changes landfill design requirements, as the stabilised waste requires less extensive environmental control systems. German regulations have effectively mandated this approach by requiring that landfilled materials meet strict limits on organic content and respiration activity, essentially requiring pre-treatment before disposal.

![]()

“Mechanical Biological Treatment” from www.ciwm.co.uk and used with no modifications.

Australia's Phytocapping Solutions

Australia has developed innovative approaches to final cover systems through phytocapping, which uses specially selected vegetation and engineered soil layers to manage infiltration through evapotranspiration. Unlike traditional barrier systems that attempt to block water entry, phytocapping works with natural processes by establishing deep-rooted vegetation that intercepts and transpires moisture before it can percolate into the waste mass.

This approach offers particular advantages in arid and semi-arid regions where traditional clay caps are prone to desiccation cracking. The vegetation component provides additional benefits including carbon sequestration, habitat creation, and aesthetic improvements. Extensive research in Australia has demonstrated that properly designed phytocaps can achieve performance equivalent to conventional barrier systems while requiring less maintenance and providing greater resilience to climate variations.

Daily Operations That Make or Break a Landfill

While design establishes a landfill's foundation, daily operational practices ultimately determine its environmental performance, community acceptance, and financial sustainability. Even the most sophisticated engineering cannot compensate for poor operational execution. Successful facilities maintain rigorous operational protocols that address waste acceptance, placement techniques, environmental controls, and community relations. For more insights on preparing landfill designs, you can refer to this comprehensive guide.

Waste Acceptance Procedures

Effective waste screening begins at the scale house, where loads undergo visual inspection and documentation review before entering the facility. Many operations now incorporate radiation detection equipment, random load inspections, and digital documentation systems to verify compliance with acceptance criteria. Advanced facilities may employ automated license plate recognition and customer profiling systems that flag accounts with previous compliance issues for enhanced scrutiny.

Once past initial screening, loads proceed to active disposal areas where spotters direct traffic and perform secondary inspections during unloading. These spotters serve as the final line of defence against prohibited wastes, identifying and rejecting non-conforming materials before they enter the waste mass. This multi-layered approach to waste screening protects environmental systems while ensuring regulatory compliance and worker safety.

“integrated waste management …” from www.eurofins.com and used with no modifications.

Compaction Techniques for Maximum Density

Effective compaction represents the single most important operational factor affecting landfill capacity utilisation. Modern compaction strategies employ specialised equipment—typically steel-wheeled compactors weighing 60,000+ pounds—operated in systematic patterns that maximise waste density. The most effective techniques involve spreading waste in thin lifts (12-24 inches), making multiple passes with compaction equipment, and maintaining optimal moisture content in the waste mass. For a deeper understanding of the equipment used, explore the comparison of bulldozers vs landfill compactors.

“Macpactor | Compaction Technology …” from macpactor.com and used with no modifications.

Advanced operations monitor compaction performance through density testing, GPS-based pass counting systems, or aerial surveys that track airspace consumption rates. These measurements provide objective performance metrics that can guide operational improvements and equipment selection decisions. Some facilities now employ machine control systems that provide real-time feedback to operators, indicating when sufficient compaction has been achieved based on equipment response.

- Spread waste in thin lifts (12-24 inches maximum)

- Make 3-5 passes with compaction equipment

- Maintain proper slope during placement (typically 3:1 to 4:1)

- Track performance through regular density measurements

- Adjust equipment selection and operating patterns based on waste composition

Odour Control Strategies That Actually Work

Odour management represents one of the most challenging aspects of landfill operations, particularly for facilities near populated areas. Effective control strategies begin with proactive operational practices, including prompt waste covering, minimising open working faces, and strategic scheduling of odour-generating activities during favourable atmospheric conditions. These fundamental approaches prevent odour formation more effectively than attempting to treat odours after they develop.

Managing Operations During Extreme Weather

Weather events present unique operational challenges that require specialised procedures and contingency planning. Successful operations develop weather-specific protocols that address temperature extremes, precipitation events, and high wind conditions. These plans typically include alternative disposal locations, modified cover practices, supplemental equipment needs, and adjusted staffing requirements to maintain environmental compliance during challenging conditions.

Wet weather operations particularly test a facility's design and operational readiness. Well-designed all-weather disposal areas incorporate stabilised surfaces, adequate drainage, and designated bad-weather access routes that remain functional during precipitation events. These areas typically feature enhanced foundation layers capable of supporting collection vehicles and operational equipment without rutting or destabilisation when saturated.

Turning Landfill Problems into Opportunities

Forward-thinking operators increasingly view landfills not simply as disposal facilities but as resource recovery opportunities and potential community assets. This perspective transforms traditional “problems” into valuable resources through innovative technologies and creative partnerships. The most successful operations integrate resource recovery into their fundamental business model rather than treating it as an afterthought.

Gas management exemplifies this evolution from problem to opportunity. What was once viewed primarily as a compliance issue and potential liability has become a valuable revenue stream through energy development. Similar transformations are occurring with leachate management, buffer lands, and post-closure property utilisation as operators recognise untapped value in these traditionally challenging aspects of landfill management.

This shift toward viewing landfills as resource centres rather than disposal endpoints aligns with broader sustainability goals while improving financial performance. It also enhances community relations by demonstrating commitment to environmental stewardship beyond minimum regulatory requirements.

Landfill Resources and Their Potential Uses

Landfill Gas: Electricity generation, renewable natural gas, direct thermal applications

Buffer Lands: Wildlife habitat, agricultural production, recreational amenities

Closed Airspace: Solar energy development, recreational facilities, commercial/industrial platforms

Leachate: Nutrient recovery, industrial process water (after treatment)

Daily Cover: Beneficial use of appropriate industrial byproducts

Converting Landfill Gas to Electricity

Landfill gas-to-energy (LFGTE) systems have evolved from simple flaring operations to sophisticated power generation facilities that produce reliable renewable energy. Modern systems typically employ reciprocating engines, gas turbines, or microturbines, depending on gas quantity and quality. The most advanced projects now incorporate gas upgrading systems that produce renewable natural gas (RNG) suitable for pipeline injection or vehicle fuel applications, commanding premium prices in renewable fuel markets.

Creating Wildlife Habitats in Buffer Zones

Buffer zones required for regulatory compliance represent significant opportunities for habitat creation and ecological enhancement. These areas often comprise substantial acreage that can support native vegetation communities, pollinator habitats, or managed wildlife corridors. Many facilities have partnered with conservation organisations to develop and implement habitat management plans that enhance ecological value while maintaining necessary buffer functions.

Thoughtfully designed habitat projects can provide multiple benefits beyond ecological enhancement. They often reduce long-term maintenance costs compared to traditional landscaping approaches, create positive community perceptions, and support regulatory compliance through improved stormwater management and erosion control. Some facilities have achieved formal recognition through certification programs such as the Wildlife Habitat Council, demonstrating their environmental commitment to regulators and communities.

Successful habitat projects typically begin with detailed ecological assessments that identify existing natural resources and enhancement opportunities. The most effective plans work with site-specific conditions—soils, hydrology, adjacent land uses—rather than imposing generic templates. They also establish realistic maintenance expectations and monitoring protocols to ensure long-term sustainability after implementation.

Operators considering habitat development should consider the following approaches:

- Focus on native plant species adapted to local conditions

- Create structural diversity through varied vegetation heights and densities

- Incorporate water features where compatible with site operations

- Establish connections to surrounding natural areas where possible

- Develop partnerships with local conservation organisations for implementation support

Post-Closure Land Use Success Stories

Closed landfills increasingly serve as platforms for beneficial community uses ranging from passive recreation to commercial development. Mount Trashmore in Virginia Beach transformed a former landfill into a 165-acre park featuring athletic fields, picnic areas, and playgrounds that now hosts over one million visitors annually. In Hartford, Connecticut, the former landfill now supports a 40-acre solar array generating clean energy while providing long-term revenue through property leases, demonstrating how post-closure planning can convert environmental liabilities into community assets.

Next-Generation Landfill Designs on the Horizon

The future of landfill design points toward “smart” facilities that integrate advanced monitoring technologies, automated operational systems, and enhanced resource recovery capabilities. These next-generation designs will leverage real-time data to optimize daily operations while providing unprecedented environmental protection through early detection and intervention systems. They will also incorporate flexibility to adapt to changing waste streams as diversion programs increasingly remove recyclable and organic materials from disposal channels.

Smart Landfills with Remote Monitoring

Tomorrow's landfills will incorporate extensive sensor networks providing continuous data on critical parameters, including leachate levels, gas concentrations, waste temperatures, and settlement rates. These systems will transmit real-time information to centralised management platforms that analyse trends, predict potential issues, and automatically adjust operational systems. Operators will access this information through intuitive dashboards available on mobile devices, allowing responsive management even when off-site.

Mining Landfills for Resources

Landfill mining represents an emerging approach that views existing disposal sites as material and energy resources rather than permanent repositories. These projects excavate previously landfilled materials for resource recovery, volume reduction, or site remediation purposes. Advanced processing systems can recover metals, plastics, soil, and other valuable materials while simultaneously generating refuse-derived fuel from the remaining waste fraction.

While still evolving, this approach offers particular promise for older unlined facilities that present environmental concerns or where land values justify reclamation efforts. Successful projects in Europe have demonstrated recovery rates exceeding 50% by weight, substantially reducing the volume requiring redisposal while generating revenue from recovered materials.

Materials Typically Recovered in Landfill Mining

Ferrous Metals: 1-5% (varies by waste age and source)

Non-Ferrous Metals: 0.5-2% (aluminum, copper, etc.)

Soil/Cover Material: 40-60% (can be reused as daily cover)

Plastics: 5-15% (recovery rates declining with waste age)

Combustible Fraction: 15-30% (potential RDF/SRF material)

Implementation challenges include uncertain material composition, potential environmental releases during excavation, and high processing costs. However, advancing technology and growing interest in circular economy principles continue to improve the economic viability of these projects, particularly when environmental remediation benefits are included in the value proposition.

Frequently Asked Questions

As landfill designs become more sophisticated, both professionals and community members frequently seek clarification on how these facilities function, what environmental protections they incorporate, and what happens after they close. The following questions address common inquiries about modern landfill design and operation.

How long does a modern landfill typically remain operational?

Operational lifespans for modern landfills typically range from 20-50 years, depending on design capacity, incoming waste volumes, and compaction efficiency. Large regional facilities may operate for 50+ years through phased expansion, while smaller local facilities might reach capacity in 15-20 years. Actual lifespans often exceed original projections as waste diversion programs, improved compaction techniques, and operational optimisations extend useful capacity.

Facilities designed with significant vertical capacity (above-grade filling) generally achieve longer operational lifespans than those limited to at-grade configurations. The availability of expansion property also significantly impacts longevity, as many facilities substantially extend their useful lives through horizontal expansion onto adjacent parcels acquired during initial operations.

What happens to a landfill after it reaches capacity?

When a landfill reaches its permitted capacity, it undergoes final closure—a carefully engineered process that caps the facility with multiple protective layers designed to minimise infiltration, support vegetation, and control gas emissions. This final cover system typically includes a barrier layer (clay and/or geomembrane), drainage layer, protective soil layer, and vegetation cover. The specific design varies based on climate, regulatory requirements, and planned end use.

After closure, the facility enters post-closure care—a period typically lasting 30+ years during which environmental systems continue operating while the site transitions to its next use. During this period, operators maintain the cover system, operate leachate and gas management systems, conduct environmental monitoring, and implement any necessary remedial actions.

In many landfill examples, these facilities develop beneficial end uses during this period, converting the property to recreational, commercial, or energy production purposes.

Are modern landfills completely safe for nearby communities?

Modern landfills incorporate multiple engineered systems specifically designed to protect human health and the environment, making them substantially safer than historical disposal practices. However, like all engineered facilities, they cannot guarantee zero impact under all circumstances. Responsible operators acknowledge potential concerns while implementing comprehensive monitoring programs that verify protection systems are functioning as designed and provide early warning of any issues requiring attention.

How do landfills prevent contamination of groundwater?

Modern landfills protect groundwater through multiple defensive systems working in concert. The primary protection comes from composite liner systems that combine low-permeability soil layers with geomembrane barriers to prevent leachate migration. Above these liners, leachate collection systems remove liquid from the waste mass before it can accumulate and exert pressure on the liner. These physical barriers are supplemented by extensive groundwater monitoring networks that provide early detection of any potential impacts, allowing intervention before off-site migration could occur.

Can all types of waste go into the same landfill?

No, different waste types require different management approaches and containment designs. Municipal solid waste landfills typically accept household waste, commercial waste, and non-hazardous industrial waste but prohibit hazardous waste, liquid waste, and certain special wastes like PCBs. Hazardous waste requires disposal in specially designed secure landfills with enhanced containment features. Construction and demolition debris often goes to dedicated C&D landfills with modified design requirements reflecting the inert nature of these materials.

Even within permitted landfills, certain wastes may require special handling procedures. Asbestos-containing materials, for example, typically require dedicated disposal areas with specific management protocols to prevent fibre release. Similarly, high-moisture wastes or materials with significant odour potential may be directed to specialised working faces with enhanced operational controls.

Understanding these distinctions helps waste generators properly direct materials to appropriate facilities while helping operators maintain compliance with their specific permit conditions. Proper waste classification represents the first step in ensuring environmental protection through appropriate containment and management approaches. For more detailed information, you can explore landfill design specifications.

Landfill Examples: A Conclusion

As you've seen from the landfill examples shown here, the evolution of landfill design continues to advance with new technologies, enhanced understanding of long-term performance, and changing waste stream characteristics.

By incorporating these innovations while maintaining fundamental environmental protection principles, waste management professionals can develop disposal facilities that serve essential public health functions while minimising environmental impacts and maximising resource recovery opportunities.

The Problem of Expansive Soils

The Problem of Expansive Soils: When building or buying a new house, property owners usually obsess over style, furniture, gardens, pools – but they can forget one critical factor: the soil. Expansive soils can cause damage to buildings. Research has shown that one in four houses in the US has been somehow affected by this. […]

Small-Scale Separators for Dairy Farms and AD Plants

New Small-Scale Separator is Big on Results Following the success of its acclaimed Separators since their launch in 2016, Borger has released a new, affordable, 25 m³/h model, suitable for dairy farmers with herds of up to 150 – and for small-scale biogas operators. The launch of this compact new Bioselect RC 25 Small-Scale Slurry Separators (which […]

The Skip Hire Operator's Duty of Care (UK) – Updated Legal Framework

Skip Hire operator's Duty of Care (UK) requirements for Skip Hire Service Companies are poorly understood by the public and even by some skip hire companies and other waste transport operators. Why the UK's Duty of Care Regulations Were Introduced for the Transport Sector Most nations suffer fly-tipping problems and the UK response has been […]

List of Old Landfill Sites Going Solar – Solar Landfills

Many old landfill sites are going solar so we thought we would create a list of 10 recent examples of landfill sites going solar, which have in the News, over the past 6 months. They are being made into what we call “Solar Landfills”, and its great news for the environment because solar energy is […]