What's Landfill Gas? Landfill gas is a mixture of methane and carbon dioxide produced by the anaerobic decomposition (rotting) of organic waste in landfills, but it can be much more than that. It also contains other trace gases, including hydrogen sulfide, which gives it an unpleasant odour. While landfill gas is a highly damaging greenhouse gas, capturing it for energy production can reduce global warming and provide an energy source. Read on and find out how collecting and using landfill gas can be huge for saving the planet from global warming!

Key Takeaways

- Landfill gas is a natural byproduct of organic waste decomposition, primarily composed of 50% methane and 50% carbon dioxide, making it a valuable renewable energy source.

- When captured and utilised properly, landfill gas offers significant environmental benefits, including reduced greenhouse gas emissions equivalent to removing millions of cars from the road.

- Modern collection systems can convert landfill gas into electricity, heat, or renewable natural gas, providing economic benefits to municipalities and reducing dependence on fossil fuels.

- Landfills can continue producing gas for over 50 years, with peak production occurring 5-7 years after waste disposal.

- Without proper management, landfill gas can contribute to climate change, cause odour problems, and potentially pose health risks to nearby communities.

Beneath our everyday trash lies an invisible resource with remarkable potential. As your waste decomposes, it's actually creating a valuable energy source.

Landfill gas represents one of the most overlooked resources in our waste management systems. This naturally occurring byproduct of decomposition offers significant environmental and economic benefits when properly harnessed. The Environmental Protection Agency recognises landfill gas energy projects as important components in reducing methane emissions while providing clean energy alternatives to fossil fuels.

From powering homes to fueling vehicles, landfill gas demonstrates how even our waste can become valuable when we apply innovative thinking. But to truly understand its benefits, we need to explore what landfill gas is, how it's created, and the remarkable ways it can be transformed from an environmental liability into a sustainable asset.

“File: Landfill Gas Vents (in the foreground, not on the horizon) – geograph.org …” from commons.wikimedia.org and used with no modifications.

What Exactly Is Landfill Gas and Why Should You Care?

Landfill gas (LFG) is a natural byproduct created when organic material decomposes in a landfill. Unlike natural decomposition in open environments, the buried waste in landfills breaks down in an oxygen-deprived (anaerobic) environment, producing a gas mixture that's approximately half methane and half carbon dioxide, along with small amounts of non-methane organic compounds. For more information on the impact of methane emissions from landfills, you can explore potential problems and solutions.

Why should this matter to you? Because every time you throw away food scraps, paper products, yard trimmings, or other organic materials, you're contributing to this invisible energy source. When properly captured, this gas can generate electricity, heat buildings, power vehicles, and even be refined into renewable natural gas that's chemically identical to conventional natural gas.

Without collection and control systems, landfill gas can contribute significantly to climate change since methane is a potent greenhouse gas. It can also cause unpleasant odors, damage vegetation, create explosion hazards if it migrates and concentrates in enclosed spaces, and potentially impact local air quality. This makes landfill gas management not just an energy opportunity but an environmental necessity.

The Basic Chemistry of Landfill Gas

Understanding the composition of landfill gas helps explain its value and the challenges it presents. This isn't simply “garbage gas” – it's a complex mixture with specific properties that make it both useful and potentially problematic.

Methane and Carbon Dioxide: The Main Components

The primary components of landfill gas – methane (CH₄) and carbon dioxide (CO₂) – typically make up 90-98% of the total gas volume. Methane usually constitutes about 50% of landfill gas and is the same primary component found in natural gas that heats millions of homes. This methane content gives landfill gas its energy value and makes it a renewable alternative to fossil fuels.

Carbon dioxide makes up most of the remaining volume, typically around 50%. While not energy-producing itself, understanding its presence is important for processing the gas and calculating environmental impacts. This basic composition remains relatively consistent across different landfills, though percentages can vary based on waste composition, age, and environmental conditions.

“Landfill gas utilization – Wikipedia” from en.wikipedia.org and used with no modifications.

Trace Gases That Can Cause Health Issues

Beyond methane and carbon dioxide, landfill gas contains small amounts of nitrogen, oxygen, hydrogen, and trace amounts of over 100 different non-methane organic compounds (NMOCs). These include volatile organic compounds (VOCs), hazardous air pollutants (HAPs), and odorous compounds like hydrogen sulfide and ammonia.

These trace components typically make up just 2-10% of landfill gas, but they're important to consider. Hydrogen sulfide creates the “rotten egg” smell often associated with landfills, while ammonia contributes to the general unpleasant odour. Some VOCs can be harmful to human health in high concentrations or with long-term exposure, which is why proper gas collection systems are essential at modern landfills.

Typical Landfill Gas Composition

Methane (CH₄): 45-60%

Carbon Dioxide (CO₂): 40-60%

Nitrogen (N₂): 2-5%

Oxygen (O₂): 0.1-1%

Other Trace Gases: 0.1-1%

How Decomposition Creates These Gases

The generation of landfill gas happens through a fascinating biological process. When organic waste is first deposited in a landfill, aerobic bacteria (which require oxygen) begin breaking it down. As these bacteria consume oxygen, the environment becomes anaerobic, and different bacteria take over the decomposition process.

The 50+ Year Production Timeline

Landfill gas production follows a remarkably long timeline that far exceeds what many people realise. While most active waste management planning focuses on the first decade after disposal, landfills can continue producing significant quantities of gas for over 50 years. This extended production period creates long-term opportunities for energy recovery while also necessitating decades of environmental monitoring.

The longevity of gas production depends largely on the composition of waste in the landfill. Paper products and other cellulose materials break down slowly, creating a sustained release of methane long after a landfill has closed and been capped. This persistence means that even landfills closed in the 1970s and 1980s may still generate enough gas today to warrant collection systems and potentially support energy recovery projects.

“Landfill gas utilization – Wikipedia” from en.wikipedia.org and used with no modifications.

Peak Production Periods (5-7 Years After Waste Disposal)

Though landfills produce gas for decades, they don't generate consistent volumes throughout this period. Gas production typically follows a bell curve, with minimal production during the first year as the waste begins to decompose anaerobically. Production then accelerates rapidly, usually reaching its peak between 5-7 years after waste placement as the optimal bacterial activity and decomposition rates are achieved.

During this peak period, a well-designed landfill gas collection system can capture 60-85% of the methane produced, maximising both environmental protection and energy recovery potential. This sweet spot in gas production makes years 5-15 particularly valuable for energy generation projects, when outputs are highest and most consistent.

- Initial Phase: Minimal gas production during the first 6-12 months

- Growth Phase: Rapidly increasing gas production from years 1-5

- Peak Production: Maximum gas generation during years 5-7

- Decline Phase: Gradual reduction in gas production from years 7-50+

Understanding this production timeline is crucial for planning energy recovery projects. The most successful initiatives account for this natural curve, often installing scaled collection systems that can be expanded during peak years and contracted during decline phases. This adaptability ensures economic viability throughout the system's operational life.

Modern landfill gas modelling can predict production curves with impressive accuracy, allowing operators to forecast energy output and revenue streams for decades. These predictive tools have transformed landfill gas from an uncertain byproduct into a bankable energy resource that attracts significant investment from utilities and energy companies.

“Landfill Gas Emission Reduction in …” from encyclopedia.pub and used with no modifications.

Factors That Speed Up or Slow Down Gas Production

The rate of landfill gas production isn't fixed and can be significantly influenced by both environmental factors and operational decisions. Moisture content stands as the single most important variable affecting decomposition rates and subsequent gas production. Landfills in rainy regions typically produce gas more quickly than those in arid areas, while controlled addition of moisture through leachate recirculation can increase gas production by 30-50% in some cases.

Temperature also plays a critical role in bacterial activity and gas generation. Decomposition occurs most efficiently at temperatures between 90-95°F (32-35°C), with significant slowdowns below 50°F (10°C). This temperature sensitivity creates seasonal variations in gas production in many regions and explains why landfills in warmer climates often achieve higher gas yields.

Other influential factors include waste composition (with higher organic content producing more gas), compaction density, landfill depth, and the presence of inhibitory compounds that might slow bacterial activity. Landfill operators increasingly manipulate these factors intentionally to optimise gas production, essentially treating their facilities as bioreactors rather than simple waste repositories.

Turning Trash Gas Into Treasure: Energy Recovery

The transformation of landfill gas from an environmental liability into a valuable energy resource represents one of waste management's greatest success stories. Rather than simply flaring (burning) captured gas to reduce environmental impact, modern systems convert this methane-rich resource into various forms of usable energy that offset fossil fuel consumption while generating revenue for municipalities and landfill operators.

How Landfill Gas Becomes Electricity

The most common application for captured landfill gas is electricity generation, a process that typically utilises internal combustion engines, gas turbines, or microturbines, depending on the volume of gas available. Once collected, the gas undergoes treatment to remove moisture and contaminants before being fed into these generation systems.

A medium-sized landfill gas electricity project can generate enough power for approximately 1,600 homes, creating significant renewable energy while reducing methane emissions.

- Internal Combustion Engines: Most common for landfills producing 1-3 million cubic feet of gas daily

- Gas Turbines: Efficient for larger operations with 3+ million cubic feet per day

- Microturbines: Suitable for smaller landfills or declining production phases

- Fuel Cells: Emerging technology offering higher efficiency but at greater capital cost

The electricity generated can be used on-site to power landfill operations or exported to the grid under various arrangements with local utilities. Power purchase agreements (PPAs) often provide guaranteed pricing for 10-20 years, creating predictable revenue streams that help finance the initial collection and generation infrastructure. For more information on landfill gas, visit this landfill gas resource.

Beyond the direct energy benefits, these projects generate valuable renewable energy credits (RECs) that can be sold separately from the electricity itself, enhancing the economic viability of these initiatives. In many regions, landfill gas energy qualifies for premium pricing under renewable portfolio standards, further improving project economics while helping utilities meet their mandated clean energy targets.

Direct Use Applications for Heating

While electricity generation receives the most attention, direct use of landfill gas for heating applications often provides greater efficiency and economic returns. Medium-quality landfill gas can be piped directly to nearby industrial facilities, replacing natural gas in boilers, kilns, dryers, and other thermal applications with minimal processing.

This approach eliminates the efficiency losses inherent in electricity generation and transmission, allowing facilities to utilise up to 90% of the energy content compared to roughly 33% for electrical applications. Successful direct use projects include supplying gas to manufacturing plants, greenhouses, college campuses, and district heating systems, often through partnerships with facilities located within a five-mile radius of the landfill. To learn more about the various uses of landfill gas, explore our comprehensive guide.

Renewable Natural Gas Production

The highest-value application for landfill gas is conversion to renewable natural gas (RNG), a purified product that meets pipeline quality standards and is chemically identical to conventional natural gas. This process removes carbon dioxide, nitrogen, oxygen, and trace contaminants, leaving nearly pure methane that can be injected into natural gas pipelines or used as compressed natural gas (CNG) vehicle fuel.

Though requiring significant initial investment in purification equipment, RNG commands premium pricing in the transportation sector, where it helps meet renewable fuel standards, making it increasingly attractive as processing costs decline and environmental incentives increase.

“Biogas-Renewable natural gas – U.S …” from www.eia.gov and used with no modifications.

Modern Collection Systems Explained

The foundation of any landfill gas project is an effective collection system that safely captures the gas before it can escape to the atmosphere. These engineered networks of wells, pipes, and processing equipment represent significant infrastructure investments but are essential for both environmental protection and energy recovery. Modern collection systems can achieve capture rates of 60-90% of the total landfill gas produced, dramatically reducing methane emissions while creating a consistent gas supply for energy projects.

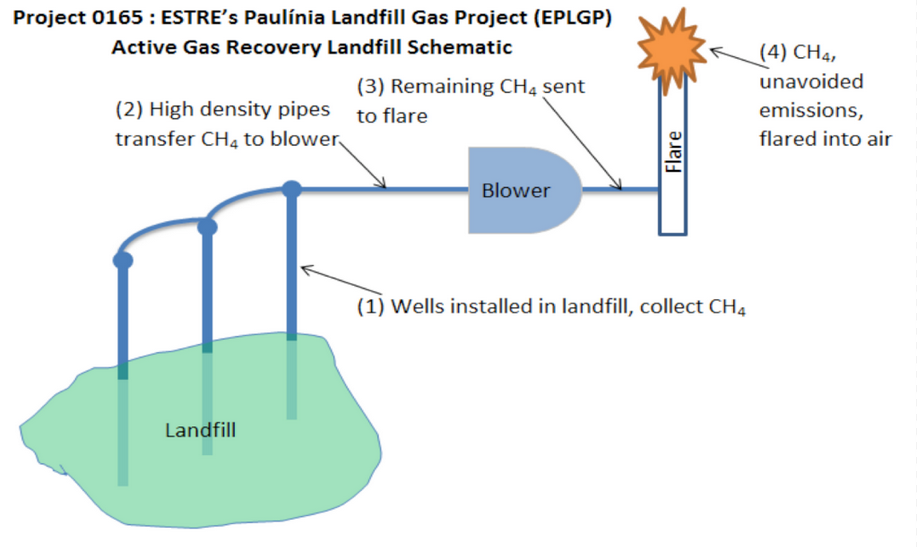

Vertical Wells and Horizontal Collectors

The most common collection method involves a network of vertical wells drilled into the waste mass, typically spaced 100-200 feet apart and extending to within 10-15 feet of the landfill bottom.

These perforated pipes create a vacuum that draws gas from the surrounding waste into the collection system, with each well typically influencing a radius of about 100 feet.

In active landfill areas still receiving waste, horizontal collectors – perforated pipes laid horizontally in trenches as the waste is placed – allow gas collection to begin even before sections reach final grade. The most effective systems combine both approaches, with horizontal collectors capturing gas during active filling and vertical wells installed after sections reach final elevation.

Blower and Flare Systems

At the heart of every collection system is a central blower station that creates the necessary vacuum to draw gas from throughout the landfill into a centralised location. These blowers maintain precise negative pressure that pulls gas through the well field without drawing excessive oxygen into the waste mass, which could inhibit anaerobic decomposition or create fire risks.

- Primary Blowers: Create a vacuum throughout the well field

- Secondary Blowers: May boost pressure for delivery to energy recovery equipment

- Enclosed Flares: Burn excess gas or serve as backup during maintenance

- Condensate Management: Removes moisture that accumulates in the collection system

The flare system serves as both an emissions control device and a safety feature. During startup, system maintenance, or when gas production exceeds energy recovery capacity, the flare destroys methane and volatile organic compounds with combustion temperatures exceeding 1,500°F, converting methane to carbon dioxide and water vapor – reducing its global warming potential by 96%.

Modern enclosed flares achieve destruction efficiencies exceeding 98% for methane and most non-methane compounds, making them remarkably effective pollution control devices even when beneficial use isn't possible. Though flaring was once the primary management approach, today's systems prioritise energy recovery and use flares primarily as backup systems.

Monitoring Technology and Safety Controls

Advanced monitoring systems form the backbone of effective landfill gas management, continuously tracking gas composition, flow rates, temperature, and pressure throughout the collection network. Automated systems adjust well field vacuum levels in real-time to optimize collection while preventing oxygen intrusion, with alarms alerting operators to any conditions that might indicate problems or safety concerns.

Regular surface emissions monitoring using portable detection devices helps identify any areas where gas might be escaping the collection system, allowing prompt repairs or adjustments to maintain capture efficiency and minimise environmental impact.

Landfill Gas Regulations You Should Know

Landfill gas management is heavily regulated in the United States and many other countries, reflecting both its environmental implications and energy potential. These regulations have evolved significantly since the 1990s when the first major federal rules targeted landfill emissions. Understanding the regulatory framework is essential for landfill operators, nearby residents, and stakeholders involved in energy recovery projects.

The regulatory landscape for landfill gas combines emissions control requirements with incentives for beneficial use projects. This dual approach recognises that proper management provides both environmental protection and energy benefits. The framework continues to evolve as our understanding of climate impacts grows and technologies improve.

EPA Requirements for Large Landfills

The primary federal regulations governing landfill gas come from the EPA's New Source Performance Standards (NSPS) and Emission Guidelines under the Clean Air Act. These rules require municipal solid waste landfills exceeding certain size thresholds and emission rates to install and operate gas collection and control systems.

Specifically, landfills with a design capacity of 2.5 million metric tons or more that emit 34 metric tons of non-methane organic compounds annually must capture and control their gas emissions. Once installed, these systems must achieve at least 98% destruction efficiency for non-methane organic compounds or reduce them to less than 20 parts per million by volume.

State-Level Variations in Regulation

- California has the strictest standards, requiring collection systems at smaller landfills and mandating more comprehensive monitoring protocols

- Some states offer tax incentives or renewable energy credits specifically for landfill gas energy projects

- Northeastern states often impose stricter air quality requirements due to population density concerns

- Several states require gas collection before federal thresholds are triggered

State implementation plans (SIPs) often go beyond federal requirements, particularly in areas with air quality challenges. These state-specific regulations can include stricter collection requirements, more extensive monitoring programs, and additional reporting obligations. California's Landfill Methane Rule, for example, applies to landfills much smaller than those regulated under federal rules and requires comprehensive surface emissions monitoring on a quarterly basis.

These variations create a patchwork of requirements across the country, with landfills in some states facing significantly more stringent controls than similar facilities elsewhere. This regulatory diversity reflects different regional priorities, population densities, and air quality conditions. For multi-state waste management companies, navigating these different requirements adds complexity to operations and compliance efforts.

Beyond operational requirements, many states have also developed specific incentives for landfill gas energy projects. These include preferential rates for renewable electricity, inclusion in renewable portfolio standards, and expedited permitting processes. These incentives recognize the dual benefits of landfill gas energy – reducing emissions while generating renewable energy – and help offset the costs of collection system installation and operation.

Local regulations add another layer of complexity, with county and municipal governments sometimes imposing additional requirements related to odour control, monitoring, and public disclosure. These local rules often respond directly to community concerns about specific landfills and may address quality-of-life issues not fully covered by state or federal regulations.

Emission Testing and Compliance Standards

Compliance with landfill gas regulations requires comprehensive monitoring and regular testing. Landfills must conduct quarterly surface emissions monitoring, checking methane concentrations across the entire landfill surface to identify any leaks or “hot spots” where gas might be escaping.

They must also monitor the efficiency of control devices, track gas collection rates, and report operational data to regulatory agencies. Any exceedances of emission limits trigger corrective actions, from adjusting well field vacuum levels to installing additional collection points in problematic areas. This rigorous testing and correction process ensures that collection systems perform effectively throughout the decades-long gas generation period.

“Landfill gas – Wikipedia” from en.wikipedia.org and used with no modifications.

The Future of Waste and Gas Management

The landscape of landfill gas management continues to evolve rapidly, shaped by advancing technology, climate policies, and changing waste streams. Looking ahead, we can expect to see more sophisticated approaches to both gas collection and utilisation. Bioreactor landfills, which actively manage moisture content to accelerate decomposition and gas production, represent one promising direction.

These engineered systems can potentially double gas yields while shortening the production timeline, making energy projects more economically attractive while reducing the long-term monitoring period.

Policy initiatives increasingly recognise landfill gas projects as valuable components of climate change mitigation strategies. Enhanced tax incentives, carbon offset credits, and renewable fuel standards all contribute to improving the economics of landfill gas utilisation. In some regions, landfill gas is being positioned as a transition fuel that can help bridge the gap to a zero-carbon future while addressing emissions from existing waste.

Environmental Benefits of a Typical 3 MW Landfill Gas Project

Carbon Dioxide Equivalent Reduction: 18,000 tons/year

Equivalent to: Removing 3,000 cars from the road

Trees Needed for Same Carbon Sequestration: 21,000 acres

Energy Equivalent: 1.5 million gallons of gasoline

Typical Homes Powered: 1,900

Perhaps the most significant shift on the horizon is increased integration of landfill gas initiatives with broader waste management strategies. Source-separated organics programs that divert food waste from landfills are gaining momentum, potentially reducing future gas production.

However, these programs are complemented by anaerobic digestion facilities that intentionally produce biogas from food waste under controlled conditions. The resulting “biogas ecosystem” maximises methane capture and utilisation across multiple waste streams, creating a more comprehensive approach to both waste management and renewable energy production.

As technology advances, smaller landfills previously considered too small for economical gas projects are finding viable options through modular systems and shared processing facilities. This democratisation of landfill gas technology extends the environmental and economic benefits beyond just the largest facilities, creating opportunities for communities of all sizes to transform their waste management challenges into renewable energy assets.

Frequently Asked Questions

Landfill gas management raises many questions for community members, policymakers, and industry professionals. Here are answers to some of the most common queries about this complex but important topic.

Is landfill gas dangerous to people living near landfills?

Modern landfills with properly functioning gas collection systems pose minimal risk to nearby residents. The EPA has established strict regulations requiring gas capture and control at larger landfills specifically to protect public health and the environment. These systems typically collect 60-90% of the gas generated, dramatically reducing potential exposures.

Without proper controls, landfill gas could potentially cause odor problems and, in rare cases, contribute to localized air pollution. The hydrogen sulfide and ammonia components are primarily responsible for odors, while volatile organic compounds in very high concentrations could potentially affect air quality. However, studies of modern landfills have generally found that off-site concentrations of these compounds remain well below health-based standards.

The greatest risk would come from gas migration through soil into enclosed spaces like basements, where methane could potentially create explosion hazards if it reached concentrations between 5-15% in air. This is why landfills monitor for subsurface gas migration and install perimeter control systems when necessary. These migration controls, combined with buffer zones around modern facilities, provide multiple layers of protection for neighbouring properties.

- Odour impacts are typically the most common community concern

- Modern collection systems dramatically reduce potential exposures

- Perimeter monitoring detects any off-site gas migration

- Buffer zones provide additional protection for neighboring properties

How much energy can be produced from landfill gas?

The energy potential from landfill gas is substantial and often underappreciated. The EPA estimates that a million tons of municipal solid waste in a landfill will produce approximately 432,000 cubic feet of landfill gas per day during peak production, enough to generate about 0.78 megawatts of electricity or provide 9 million BTUs of heat per hour.

For perspective, a typical medium-sized landfill receiving 1,000 tons of waste daily could generate enough electricity to power approximately 1,900 homes when operating at peak capacity. When converted to renewable natural gas for vehicle fuel, the same landfill could fuel about 150 garbage trucks or other heavy-duty vehicles, creating a circular economy where today's waste powers tomorrow's waste collection.

What happens if landfill gas isn't properly collected?

Uncollected landfill gas creates several significant problems. From an environmental perspective, the methane emissions contribute substantially to climate change, as methane is 25 times more potent as a greenhouse gas than carbon dioxide over a 100-year period. A mid-sized uncontrolled landfill can have the climate impact equivalent to emissions from 22,000 passenger vehicles.

Beyond climate impacts, uncollected gas can cause unpleasant odors that affect quality of life in surrounding communities, potentially reducing property values and triggering nuisance complaints. In extreme cases, lateral migration of methane through soil can create safety hazards if the gas accumulates in enclosed spaces like utility vaults, basements, or structures. The leaking gas can also damage vegetation around landfill perimeters by displacing oxygen in the root zone, creating barren areas that contribute to erosion problems and visual impacts.

Can small landfills also capture and use their gas?

Yes, technological advances have made gas collection and utilization increasingly viable for smaller landfills. While federal regulations only require collection systems at larger facilities, many smaller landfills voluntarily install them for environmental, economic, or community relations benefits.

Small-scale options include microturbines that can generate electricity with as little as 100 cubic feet per minute of landfill gas, direct-use projects that supply boilers or kilns at neighbouring facilities, and cooperative arrangements where several small landfills pipe their gas to a central processing facility. The economics improve further when carbon offset credits or renewable energy incentives are available, sometimes making projects viable at landfills with as little as 500,000 tons of waste in place.

How does weather affect landfill gas production?

Weather conditions have a significant impact on both landfill gas production and collection efficiency. Precipitation is particularly influential, as moisture is essential for the anaerobic bacteria that produce methane. Landfills in wetter climates typically generate gas more quickly and at higher volumes than those in arid regions. Heavy rainfall events can temporarily boost gas production by increasing moisture throughout the waste mass, though excessive precipitation can sometimes flood collection wells and reduce system efficiency.

Temperature affects bacterial activity directly, with gas production typically increasing in warmer months and decreasing during cold periods. This seasonal variation can be substantial in northern climates, with winter production sometimes dropping by 15-30% compared to summer peaks. Barometric pressure changes also influence gas collection, as falling pressure (as during storms) can increase gas flow from the landfill while rising pressure can temporarily suppress it.

Collection system operators must constantly adjust to these weather-related variables, modifying vacuum levels and flow rates to maintain optimal performance regardless of external conditions. Modern systems increasingly incorporate weather data into their control algorithms, automatically adjusting to changing conditions to maximise collection efficiency throughout the year.

Weather effects also explain why landfill odours sometimes seem worse during specific conditions. Temperature inversions can trap gas near the ground surface, while rapid barometric pressure drops can release more gas than the collection system can immediately capture. Understanding these weather-related dynamics helps operators anticipate and mitigate potential community impacts.

How to Reduce Methane Emissions at Home

Many homes contribute to methane emissions without knowing it. Methane is a potent greenhouse gas that harms our environment. This blog will guide you through practical steps to reduce these emissions right from your home. Read on to make a change! Key Takeaways Understanding Methane Emissions What is methane and its environmental impact at home? […]

Understanding the Benefits and Drawbacks of Sanitary Landfill Sites

In this article, you will find out about the advantages and disadvantages of sanitary landfills. Deciding on the best way to handle rubbish, is a common challenge, especially in developing nations. Sanitary landfills offer one solution, but they come with pros and cons. This article will help you understand these landfill sites better, including their benefits and drawbacks. Stay […]

Landfill Sites – 3 Compelling Reasons to Bury the Use of Dumps

Landfill Sites are not sustainable, and here are 3 compelling reasons to bury the idea that we continue to use landfills (dumps) for municipal waste beyond the next 10 years. All waste has to be disposed of in a safe manner. If not it is a major health problem in densely populated urban areas, second […]

Waste Decomposition and Degradation of Waste in Landfills

Waste Decomposition: The Main Stages of waste decomposition, otherwise known as the waste degradation process An understanding of the Main Stages of waste decomposition. Which is alternatively called “the waste degradation process” is essential to understand how a landfill will gradually change over many years. We are often asked how many years will it take […]