In this long article we a complete guide to the Ramp Method of waste disposal with the techniques used to operate daily landfill cells with daily cover.

Article-At-A-Glance

- The ramp method optimizes landfill operations by creating an inclined surface that allows waste vehicles easy access to active disposal areas

- This technique maximizes available space usage while minimizing environmental impact through efficient waste compaction and daily cover application

- Unlike trench and area methods, the ramp approach requires minimal excavation and works well on sloped terrains, making it ideal for many municipal landfills

- Proper implementation can reduce operational costs by up to 30% compared to traditional disposal methods while extending landfill lifespan

- Understanding the right equipment selection and maintenance procedures ensures optimal ramp method performance even in challenging weather conditions

“Landfill operation stage: The area or ramp and …” from www.researchgate.net and used with no modifications.

When it comes to modern landfill management, efficiency isn't just about saving money—it's about maximizing space, minimizing environmental impact, and ensuring sustainable waste disposal for communities. The ramp method stands out as one of the most practical and widely-used techniques in sanitary landfilling operations today.

Waste management professionals recognize the ramp method as a cornerstone of efficient landfill design. Sustainable Waste Solutions has pioneered innovations in ramp method implementation, helping municipalities maximize their landfill capacity while reducing operational costs. This approach creates a systematically expanding disposal area that grows methodically over time, allowing for controlled waste placement and efficient land use.

Let's dive into the fundamentals of this essential waste disposal technique and discover why it continues to be a preferred method for modern landfill operations worldwide.

Ramp Method: The Most Efficient Way to Manage Landfill Operations

The ramp method represents a specialized approach to sanitary landfilling that utilizes an inclined surface (the ramp) as both the working face for waste disposal and the access route for collection vehicles. This technique creates a self-contained system where waste trucks can drive directly onto the working area, deposit their loads, and exit without complex maneuvering or separate access road construction. By continuously building upon existing waste layers at a slight angle, operators create a dynamic disposal area that grows methodically over time.

What makes this approach particularly valuable is its adaptability to various site conditions and its efficient use of available space. The method works by establishing a gradual slope against an existing hill, valley wall, or previously filled area, then systematically expanding outward as waste accumulates. This creates a continuous working face that can be adjusted based on daily waste volumes, weather conditions, and long-term capacity planning.

From an operational standpoint, the ramp method offers significant advantages in terms of equipment utilization, traffic flow management, and daily cover application. Heavy machinery like compactors and dozers can operate more efficiently on the sloped surface, achieving better waste density while consuming less fuel than on flat or excavated areas. This translates to lower operational costs and reduced environmental impact over the landfill's lifetime.

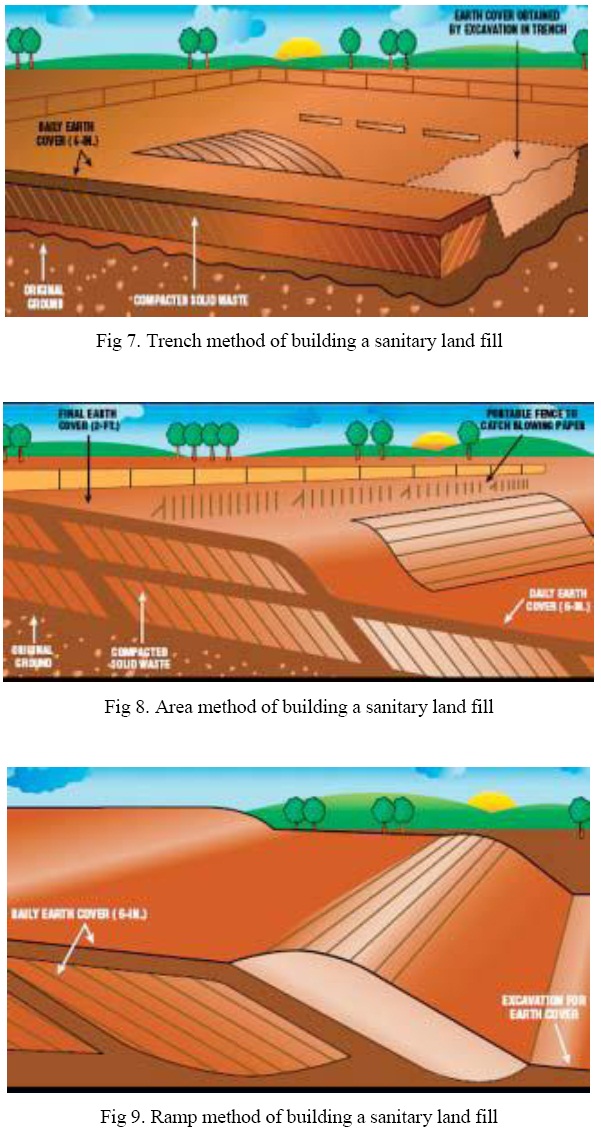

What Makes Ramp Method Different from Other Disposal Techniques

Unlike other landfilling approaches, the ramp method offers unique advantages that make it particularly suitable for certain site conditions and operational requirements. Where the trench method requires extensive excavation and the area method demands significant quantities of cover material, the ramp technique operates with minimal site preparation and optimized material usage.

The primary distinction lies in how waste placement occurs. In trench methods, operators must first dig large excavations—a process that's time-consuming, expensive, and limited by soil conditions. The area method spreads waste over existing ground, requiring massive amounts of daily cover soil to be transported to the site. The ramp method, however, creates its own progressive working area with minimal excavation, using gravity and slope to advantage while reducing the need for imported cover materials. For those interested in the cost of commercial waste disposal, understanding these methods can provide insights into potential savings.

Another key difference is accessibility. While trench operations often struggle with drainage issues and limited vehicle access during inclement weather, the ramp method's elevated working face provides natural drainage and all-weather operation capabilities. This results in fewer operational disruptions and more consistent waste processing throughout the year, particularly in regions with high precipitation or seasonal flooding risks.

“Bacteriological Pollution – an overview …” from www.sciencedirect.com and used with no modifications.

Ideal Conditions for Implementing the Ramp Method

The ramp method thrives under specific site conditions that maximize its inherent advantages. Ideal implementation sites typically feature moderate natural slopes between 3-5%, stable underlying geology, and sufficient space for lateral expansion as the landfill develops. These conditions allow for natural drainage while minimizing the need for extensive earthwork during initial site preparation. For more detailed guidance, you can refer to this Guidebook on SLF Plan Design.

From a geological perspective, sites with relatively shallow groundwater tables often favor the ramp method over trench approaches. Since minimal excavation is required, the risk of groundwater contamination can be more effectively managed through proper liner systems and leachate collection networks positioned above the natural water table. This makes the ramp method particularly valuable in areas where high water tables would otherwise preclude landfill development. For more insights into the benefits and drawbacks of sanitary landfill sites, you can explore additional resources.

The method also shows exceptional performance in locations with limited cover material availability. Because the working face is constantly advancing, cover soil can be stripped from ahead of the operation and directly applied to completed sections, creating an efficient closed-loop system that minimizes the need for imported materials. This soil conservation approach reduces both operational costs and the environmental footprint associated with cover material transportation.

- Moderate natural slopes (3-5% grade)

- Stable underlying geology without fractures or sinkholes

- Sufficient space for lateral expansion

- Limited availability of cover materials

- Relatively shallow groundwater tables

- Consistent waste volumes for continuous operation

Weather considerations also play a significant role in determining the suitability of the ramp method. The technique performs exceptionally well in regions with high seasonal rainfall, as the sloped design facilitates natural runoff while maintaining accessible working areas. This all-weather capability ensures continuous operation when other methods might face work stoppages due to saturated conditions or poor accessibility.

How the Ramp Method Actually Works in Landfills

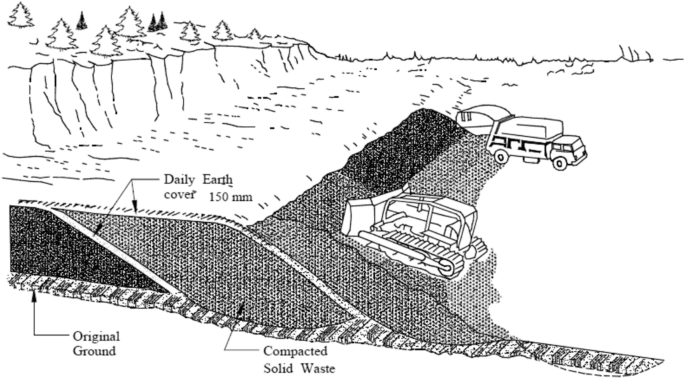

The ramp method involves creating an inclined surface where waste disposal operations take place in a systematic, advancing pattern. This technique begins by establishing a moderate slope against which trucks can deposit waste directly. As each day progresses, heavy equipment spreads and compacts the waste along this slope, creating a stable platform that serves as both the disposal area and the access route for vehicles.

What makes this method particularly effective is its self-sustaining nature. The working face continually advances across the site as waste accumulates, with previously filled areas serving as the foundation for new operations. This progressive expansion creates an efficient workflow that maximizes space utilization while maintaining accessibility for all equipment and vehicles involved in the disposal process.

The dynamic nature of the ramp method allows operators to adjust working face dimensions based on daily waste volumes, staffing levels, and equipment availability. This flexibility ensures consistent operations regardless of fluctuations in waste generation or seasonal variations that might otherwise disrupt landfill activities.

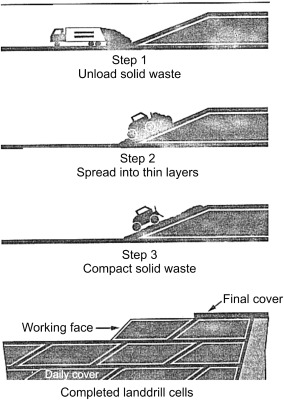

“Method Used in Landfills | Download …” from www.researchgate.net and used with no modifications.

Step-by-Step Process of Daily Operations

Daily operations begin with site preparation, where equipment operators ensure the working face is properly graded and the access road is clear of obstacles. Collection trucks then approach the active disposal area via the compacted ramp, which typically maintains a 3:1 to 4:1 slope ratio for safety and accessibility. Upon reaching the designated unloading zone at the top of the ramp, trucks deposit their waste loads before exiting via a predetermined route that minimizes cross-traffic.

Once waste is deposited, bulldozers and compactors immediately begin spreading and compacting the material in thin layers, typically 12-24 inches thick. This layering technique maximizes density and stability while reducing settlement issues that could compromise the landfill's long-term integrity. The compaction process continues throughout the day as new waste arrives, with operators working methodically to maintain proper slope angles and waste density specifications.

At the end of each operational day, a layer of daily cover material—usually 6-12 inches of soil or approved alternative—is applied over the entire working face. This cover serves multiple purposes: controlling odors, preventing windblown litter, deterring vectors like birds and rodents, and providing a stable surface for the next day's operations. The following morning, operations resume with the removal of a portion of this cover material, creating a clean tie-in point for new waste placement.

Equipment and Personnel Requirements

Successful implementation of the ramp method requires specific equipment tailored to the unique challenges of sloped waste placement and compaction. The primary machinery includes tracked bulldozers for waste spreading and slope creation, purpose-built landfill compactors for achieving maximum waste density, and excavators or wheel loaders for cover material handling. Supporting equipment typically includes water trucks for dust suppression, haul trucks for cover material transportation, and specialized monitoring vehicles for environmental compliance verification.

Personnel requirements typically include equipment operators, spotters who direct incoming waste vehicles, environmental technicians monitoring gas and leachate systems, and supervisory staff overseeing daily operations. The staffing levels vary based on landfill size and daily waste volumes, but generally require fewer personnel than other disposal methods due to the efficient workflow and consolidated working area.

Waste Placement and Compaction Techniques

Proper waste placement is critical to ramp method success. Operators typically establish a working face width of 100-150 feet to accommodate multiple trucks while maintaining efficient compaction. The waste is spread in thin, sloped layers moving upward from the bottom of the ramp, creating a terraced effect that maximizes stability and compaction effectiveness. This upward spreading technique ensures that leachate flows downward through already compacted waste, improving moisture distribution and accelerating decomposition processes.

Compaction techniques focus on achieving maximum waste density, typically targeting 1,200-1,400 pounds per cubic yard depending on waste composition. Equipment operators make multiple passes over each waste layer, using the machine's weight and specialized wheels or tracks designed specifically for waste compaction. The most effective compaction occurs when operators make 3-5 overlapping passes, with each subsequent pass offset slightly to ensure complete coverage.

Design Specifications for Effective Ramp Systems

Designing an effective ramp system requires careful consideration of numerous factors including terrain characteristics, anticipated waste volumes, equipment specifications, and regulatory requirements. The foundation of successful design lies in establishing appropriate dimensions that balance operational efficiency with space utilization and safety considerations. Engineers typically calculate these specifications based on the landfill's daily waste receipt, available footprint, and projected lifespan to create a system that will function effectively throughout the facility's operational phase.

Critical design elements include access road specifications, working face dimensions, slope calculations, and drainage infrastructure. These components must work together seamlessly to ensure efficient operations while maintaining environmental compliance and worker safety. Proper engineering also accounts for future expansion needs, closure requirements, and post-closure land use plans to create a comprehensive design that serves both immediate operational needs and long-term management objectives.

The most successful ramp system designs incorporate flexibility that allows operators to adapt to changing conditions while maintaining core operational principles. This adaptability might include provisions for seasonal adjustments, alternative daily cover systems, or modular gas collection infrastructure that can be expanded as the landfill develops.

“Sanitary Landfill Types and Design …” from link.springer.com and used with no modifications.

Optimal Dimensions: 30m Length and 15m Width Standard

Industry standards typically recommend a working face width of approximately 15 meters (50 feet) and a ramp length of about 30 meters (100 feet), though these dimensions can be adjusted based on site-specific requirements. These measurements create an optimal balance between providing sufficient space for equipment operation and limiting the exposed waste area to reduce environmental impacts like odor, litter, and leachate generation. The working face width should accommodate at least two collection vehicles simultaneously while allowing compaction equipment to operate safely alongside. For more detailed information on landfill planning and design, you can refer to this guidebook.

The 30-meter length recommendation provides adequate space for proper waste spreading and compaction while maintaining a manageable daily cover area. This length also creates sufficient distance between the active tipping area and the bottom of the ramp, reducing congestion and improving traffic flow for both collection and operational vehicles. For larger operations, these dimensions may be increased proportionally, but the ratio between width and length should generally be maintained to preserve operational efficiency. For more insights, consider exploring the benefits and drawbacks of sanitary landfill sites.

Environmental Benefits of the Ramp Method

The ramp method offers significant environmental advantages that extend beyond operational efficiency. By creating a controlled disposal environment with proper slopes and compaction, this technique substantially reduces leachate generation—the contaminated liquid that forms as water percolates through waste materials. This reduction occurs because the sloped design facilitates more effective runoff management, directing precipitation away from active disposal areas and minimizing water infiltration into the waste mass. For more insights into landfill practices, explore the benefits and drawbacks of sanitary landfill sites.

Greenhouse gas emissions are also better managed with the ramp method. The systematic nature of waste placement and daily cover application creates ideal conditions for the installation of gas collection infrastructure as the landfill develops. Collection pipes can be strategically placed within completed sections, capturing methane and other gases before they escape into the atmosphere. This captured gas can then be processed for energy recovery or safely flared to reduce its global warming potential.

Visual impact mitigation represents another environmental benefit of this disposal technique. The progressive nature of the ramp method allows for ongoing restoration and revegetation of completed sections while operations continue elsewhere on site. This phased approach minimizes the visible footprint of active disposal areas and creates natural-appearing landscapes that blend with surrounding terrain, reducing community concerns about aesthetic impacts.

“CIVIL ENGINEERING SEMINAR TOPICS …” from civilenggseminar.blogspot.com and used with no modifications.

Reduced Leachate Production

The sloped configuration inherent to the ramp method creates natural drainage pathways that significantly reduce water infiltration into the waste mass. When properly designed with slopes ranging from 3-5%, precipitation naturally flows away from active disposal areas, decreasing the volume of leachate generated by up to 40% compared to flat-surface disposal methods. This reduction translates directly to lower treatment costs, reduced environmental risks, and simplified long-term management requirements. For more detailed insights, you can refer to this sanitary landfill guide.

Better Gas Control and Collection

Gas management becomes substantially more effective with the ramp method's structured approach to waste placement. As each section reaches capacity, gas collection wells and horizontal collectors can be installed immediately, capturing methane during its peak production phase rather than waiting until final closure. This proactive approach not only reduces atmospheric emissions but also maximizes potential energy recovery from the landfill gas, creating opportunities for beneficial use through electricity generation or direct gas utilization in nearby industrial processes. For more detailed insights, you can refer to this guide on sanitary landfill processes.

Minimized Risk of Groundwater Contamination

The ramp method's reduced excavation requirements create natural buffers between waste materials and groundwater resources. By building upward rather than digging downward, this technique maintains greater separation distances between the bottom liner system and underlying aquifers, providing an additional safety factor against potential contamination. When combined with modern composite liner systems and leachate collection networks, this increased separation significantly enhances groundwater protection throughout the landfill's active life and post-closure period.

Operational Advantages That Save Time and Money

From a practical standpoint, the ramp method delivers compelling operational efficiencies that translate directly to cost savings and enhanced productivity. The consolidated working face reduces equipment travel distances, allowing bulldozers, compactors, and cover material transporters to complete more work cycles per hour than dispersed operations would permit. This concentration of activities also simplifies supervision requirements, enabling more effective oversight with fewer personnel.

Weather resilience represents another significant operational advantage. The elevated working face and sloped design naturally shed water during precipitation events, maintaining accessible conditions when other methods might require temporary closure. This all-weather capability ensures consistent waste acceptance and processing, preventing service disruptions that could impact collection schedules or require costly alternative disposal arrangements.

Equipment utilization rates typically improve under the ramp method, as machines can work continuously within a well-defined area rather than traveling extensively between multiple working locations. This concentrated operation reduces fuel consumption, decreases maintenance requirements, and extends equipment service life—all factors that contribute to lower operational costs and improved financial performance for the landfill operator.

Improved Traffic Flow for Waste Trucks

The ramp configuration creates natural one-way traffic patterns that eliminate cross-traffic conflicts and reduce vehicle congestion at the working face. Collection trucks can approach the disposal area via the ascending ramp, deposit their loads at the designated location, and continue forward to exit without complicated turning maneuvers or backing procedures. This streamlined traffic flow increases throughput capacity, reduces waiting times during peak delivery periods, and substantially enhances safety by minimizing vehicle interaction in active work zones. To learn more about waste management techniques, explore the benefits and drawbacks of sanitary landfill sites.

Maximum Use of Available Space

Space utilization efficiency ranks among the most valuable benefits of the ramp method. By achieving higher compaction densities—typically 1,200-1,400 pounds per cubic yard—this technique maximizes the waste-holding capacity of the permitted airspace, extending the landfill's operational lifespan without expanding its physical footprint. The progressive, controlled nature of the operation also allows operators to precisely manage fill sequencing, ensuring that every cubic yard of available space is utilized before site closure. For more insights on landfill operations, consider exploring the benefits and drawbacks of sanitary landfill sites.

Reduced Equipment Wear and Tear

Equipment operating on the structured slopes of a ramp method landfill experiences less stress and component wear than machines working in more challenging environments. The consistent grade and improved footing reduce transmission strain, hydraulic system pressure spikes, and undercarriage wear that commonly affect equipment operating on irregular or unstable surfaces. This reduction in mechanical stress extends service intervals, decreases major repair frequency, and ultimately lowers the lifetime operating cost of the landfill's heavy equipment fleet. For more on the benefits of sanitary landfill sites, visit our guide.

Lower Labor Requirements Compared to Other Methods

The consolidated nature of ramp method operations typically reduces staffing requirements by 15-25% compared to more dispersed disposal techniques. With activities concentrated at a single working face, fewer spotters, equipment operators, and supervisory personnel are needed to manage the same waste volume. This labor efficiency not only reduces direct operational costs but also simplifies scheduling, training, and safety management programs across the facility.

Common Challenges and How to Overcome Them

- Excessive slope erosion during heavy rainfall events

- Difficulty maintaining proper cover material during extended dry periods

- Seasonal variations affecting equipment traction and performance

- Managing traffic flow during peak delivery periods

- Controlling dust during dry, windy conditions

- Maintaining stable working surfaces when receiving high moisture content waste

Despite its many advantages, implementing the ramp method successfully requires addressing several common challenges that can impact operational efficiency and environmental performance. Proactive planning and adaptive management strategies can transform these potential obstacles into manageable aspects of daily operations, ensuring consistent performance regardless of changing conditions or unexpected circumstances. To understand more about the implications of these challenges, you can explore the benefits and drawbacks of sanitary landfill sites.

Maintaining proper slope integrity represents one of the most persistent challenges, particularly in regions with extreme weather patterns. Innovative solutions include incorporating geosynthetic reinforcement within the waste mass, establishing intermediate benches on longer slopes, and implementing comprehensive stormwater management systems designed specifically for the dynamic environment of an active landfill face. These approaches stabilize working surfaces while protecting completed areas from erosion damage that could compromise containment systems.

Space constraints sometimes challenge operators as landfills mature and available expansion areas diminish. Forward-thinking managers address this issue by implementing progressive height increases with proper engineering controls, strategically planning cell development to maximize airspace utilization, and incorporating waste-to-energy technologies that reduce volume requirements. These approaches extend operational lifespans while maintaining the fundamental benefits of the ramp method.

Seasonal variations require operational adjustments to maintain productivity throughout the year. Winter operations might include modifying working face orientation to maximize solar exposure, adjusting slope angles to improve traction on frozen surfaces, and implementing cold-weather cover systems that perform effectively without requiring extensive soil stockpiles. Summer adaptations typically focus on dust control, moisture management, and vector prevention during periods of increased biological activity.

Dealing with Heavy Rain and Weather Disruptions

Heavy precipitation events present significant challenges for ramp method operations, but strategic planning can minimize their impact. Successful operators develop comprehensive wet-weather plans that include temporary cover systems for rapid deployment, sacrificial working areas that can be quickly restored after storms pass, and alternative traffic patterns that utilize prepared all-weather access roads. These preparations ensure that even during extended rainfall, essential disposal operations can continue safely while protecting environmental control systems from weather-related damage.

Modern approaches to weather resilience also incorporate predictive planning based on meteorological forecasts. When significant storms are anticipated, operations may temporarily accelerate to process pending waste volumes, apply additional intermediate cover to inactive areas, and secure potential sources of windblown litter before conditions deteriorate. This proactive stance minimizes disruptions while maintaining environmental compliance throughout challenging weather conditions.

Managing Odor and Dust Issues

Effective odor control requires a multi-faceted approach centered on proper waste management practices. Daily cover application remains the primary defense, but supplemental measures including odor-neutralizing spray systems, strategically positioned windbreaks, and careful monitoring of potentially problematic waste streams significantly enhance effectiveness. The ramp method's concentrated working area actually simplifies odor management by containing potential sources within a well-defined zone where control measures can be focused most intensively. For further insights into effective waste management, explore the benefits and drawbacks of sanitary landfill sites.

Dust suppression demands equal attention, particularly during dry periods when cover soil and access roads can become significant particulate sources. Beyond traditional water trucks, advanced management practices include applying environmentally-friendly soil stabilizers to completed areas, maintaining vegetative cover on inactive slopes, and implementing operational adjustments during high-wind conditions. These measures protect air quality while creating healthier working conditions for landfill personnel. For more insights, explore the role of landfill compactors in waste management.

Preventing Excessive Settlement

Long-term stability depends on achieving uniform waste density throughout the landfill profile. The ramp method facilitates this goal through its layered compaction approach, but preventing differential settlement requires additional attention to waste composition and placement techniques. Operators must carefully distribute bulky or low-density materials throughout the working face rather than concentrating them in specific areas, apply consistent compaction effort across the entire waste mass, and monitor density achievements through regular testing and adjustment of operational practices.

When to Choose Ramp Method Over Trench or Area Methods

Selection between landfilling methods should be based on site-specific characteristics, operational requirements, and long-term management objectives. The ramp method particularly excels on properties with moderate natural slopes, limited excavation potential, or restrictions on available cover material. Its adaptability to varying waste volumes and compatibility with phased development make it especially valuable for facilities serving growing communities or those with seasonal disposal fluctuations.

Conversational decision-making must consider not just current conditions but anticipated future needs. The ramp method offers superior flexibility for expansion and modification as operational requirements evolve, making it particularly suitable for facilities expecting significant changes in waste composition, processing technologies, or regulatory requirements during their operational lifespan. This adaptability often justifies its selection even when initial site conditions might suggest alternative approaches.

Best Terrain Types for Ramp Implementation

Gently sloping hillsides represent ideal terrain for ramp method implementation, offering natural drainage characteristics and minimal preparation requirements before operations can begin. Sites with elevation differentials between 5-15% across their footprint allow operators to establish initial working faces against existing slopes, creating immediate operational efficiency without extensive earthwork or artificial berm construction. This natural topography integration significantly reduces startup costs while establishing sustainable long-term operational patterns. For more insights on waste management strategies, you can explore food waste processing technologies.

Size Considerations for Your Landfill Operation

The versatility of the ramp method makes it suitable for facilities ranging from small rural operations handling 50 tons per day to major metropolitan disposal sites processing thousands of tons daily. For smaller facilities, the method's efficiency reduces equipment and personnel requirements to manageable levels while maintaining environmental compliance. Larger operations benefit from the scalability of the approach, with multiple working faces potentially operating simultaneously within a coordinated management framework that maintains overall site integration and progressive development.

Ramp Method Suitability Scale

Small Facilities (≤50 TPD): Excellent choice with minimal equipment

Medium Facilities (51-250 TPD): Optimal efficiency with standard equipment

Large Facilities (251-1000 TPD): Highly effective with multiple equipment sets

Major Facilities (>1000 TPD): Excellent when used in sectional approach

Waste Volume and Type Compatibility

Waste composition significantly influences method selection, with the ramp approach demonstrating particular effectiveness for municipal solid waste streams containing diverse materials with varying compaction characteristics. The layered placement technique allows operators to distribute problematic materials—like bulky items, highly compressible components, or materials with minimal structural integrity—throughout the working face, preventing concentration that could create future stability issues. This distribution capability makes the ramp method especially valuable for facilities receiving heterogeneous waste streams from multiple collection sources. For more information on the benefits and drawbacks of different landfill methods, you can explore the benefits and drawbacks of sanitary landfill sites.

Specialized waste types sometimes require adaptations to standard ramp procedures. For example, high-moisture organics may need additional bulking materials incorporated during placement to maintain slope stability and prevent seepage. Construction and demolition debris, with its irregular shapes and sizes, benefits from modified spreading techniques that ensure proper compaction despite material inconsistencies. These adaptations maintain the fundamental advantages of the ramp method while accommodating specific waste characteristics.

Seasonal variations in waste composition—such as increased yard waste during growing seasons or higher percentages of packaging materials during holiday periods—can be readily accommodated within the ramp method framework. Operators adjust working face dimensions, compaction techniques, and cover material application based on incoming waste characteristics, ensuring consistent performance regardless of temporary changes in the disposal stream.

- Municipal solid waste (excellent compatibility)

- Construction and demolition debris (good with modified techniques)

- Commercial/industrial non-hazardous waste (excellent compatibility)

- Processed special wastes (good with appropriate permits)

- Biosolids and wastewater treatment residuals (moderate with moisture management)

- Disaster debris (excellent for temporary surge capacity)

Tips for Long-Term Ramp Method Success

- Maintain consistent slope angles throughout operations

- Rotate working face location to distribute settlement evenly

- Establish clear visual markers for daily fill limits

- Develop weather-specific operational protocols

- Create dedicated wet-weather disposal areas

- Implement progressive gas collection installation

Long-term success with the ramp method depends on consistent application of fundamental principles combined with site-specific adaptations that address unique operational challenges. Establishing comprehensive standard operating procedures that codify best practices ensures consistency even with changing personnel or conditions. These procedures should cover normal operations, contingency situations, and special circumstances that might require modified approaches to maintain environmental compliance and operational efficiency.

Regular evaluation and refinement of operational techniques represents another critical success factor. Progressive operators continuously monitor key performance indicators—including waste density achievements, cover material consumption, equipment productivity, and environmental compliance metrics—using these data to identify improvement opportunities and implement incremental enhancements to standard procedures. This continuous improvement approach maintains operational excellence throughout the facility's lifespan while adapting to evolving regulatory requirements and technological advancements.

Staff training and development play equally important roles in sustaining operational excellence. Equipment operators must understand not just machine operation but the underlying principles of waste compaction, slope stability, and environmental protection that govern ramp method implementation. Supervisory personnel require broader knowledge encompassing regulatory compliance, emergency response procedures, and long-term facility planning to effectively coordinate daily activities within the larger operational framework.

Community engagement represents a final but crucial component of long-term success. Transparent communication about operational practices, environmental protections, and future development plans builds public trust while creating opportunities for constructive feedback that can improve facility performance. This engagement becomes particularly valuable when operational changes or expansions are contemplated, as established relationships facilitate more productive discussions about community impacts and mitigation measures.

Daily Cover Material Selection

Selecting appropriate daily cover materials significantly impacts both operational efficiency and environmental performance. While traditional soil cover (6-12 inches applied daily) remains common, alternative materials including geosynthetic tarps, spray-on slurries, green waste compost, and processed construction waste often provide superior performance at lower cost. The ideal selection balances regulatory compliance, odor control effectiveness, vector deterrence, operational practicality, and conservation of valuable airspace—objectives that vary in priority depending on site-specific conditions and community considerations.

Maintenance Schedule for Access Roads

Proactive access road maintenance directly correlates with overall operational efficiency and safety performance. Successful facilities implement scheduled grading operations, typically weekly for primary access routes and daily for the active ramp itself, ensuring consistent surfaces that minimize vehicle stress and maximize traction under all conditions. Strategic application of road base materials at high-wear points, installation of geotextile underlayments in chronically soft areas, and immediate attention to emerging drainage issues prevent minor concerns from developing into major operational disruptions.

All-weather access represents a particular maintenance priority, with dedicated resources allocated to ensuring critical routes remain passable regardless of conditions. This preparation includes designated stockpiles of all-weather surfacing materials, equipment specifically assigned to road maintenance duties during precipitation events, and alternative routing plans that can be activated when primary access points become temporarily compromised. These investments pay dividends through consistent operations when other facilities might face weather-related service interruptions.

Monitoring and Adjustment Strategies

Comprehensive monitoring programs provide the data foundation for effective operational management. Regular surveys of waste placement, compaction density testing, cover thickness verification, and slope stability assessments generate actionable information that guides daily decision-making. Leading operations typically establish target parameters for each performance metric, with clear action thresholds that trigger specific responses when measurements indicate developing concerns or opportunities for improvement.

Environmental monitoring extends beyond regulatory compliance to include operational optimization opportunities. Tracking leachate generation rates in relation to precipitation events, for example, can identify areas where cover systems or drainage controls require enhancement. Similarly, correlating odor complaints with specific operational conditions or waste types helps develop targeted mitigation strategies that address root causes rather than symptoms. This data-driven approach transforms monitoring from a compliance obligation into a valuable operational tool, as discussed in this guide on sanitary landfill techniques.

Adjustment strategies must balance immediate operational needs against long-term facility development goals. When monitoring indicates suboptimal performance in specific areas, operators must determine whether conditions represent temporary anomalies requiring short-term adaptations or systemic issues demanding fundamental procedural changes. This assessment process, combining technical expertise with operational experience, ensures that adjustments address actual needs while maintaining overall operational continuity and environmental protection.

- Weekly aerial surveys to verify fill progression and volumes

- Daily compaction testing at multiple working face locations

- Quarterly slope stability assessments by qualified engineers

- Continuous weather monitoring with operational trigger points

- Monthly verification of waste-to-soil ratios and airspace consumption

- Regular performance benchmarking against industry standards

The most successful operations establish formal management review processes that regularly evaluate monitoring data, operational statistics, and environmental performance indicators against established goals. These structured reviews identify both immediate adjustment needs and longer-term improvement opportunities, creating a continuous enhancement cycle that maintains operational excellence throughout the facility's active life. For more detailed insights, consider reviewing this guide on sanitary landfill processes.

Future of Landfill Operations: Beyond the Basic Ramp Method

The evolution of waste management continues to drive innovations that enhance traditional ramp method operations. Advanced density monitoring technologies, including GPS-guided compaction systems and real-time density measurement tools, now allow operators to achieve unprecedented waste compaction levels—sometimes exceeding 1,600 pounds per cubic yard—maximizing site capacity while reducing settlement concerns. These technological innovations complement rather than replace the fundamental principles of the ramp method, enhancing its effectiveness through more precise implementation and monitoring.

Integration with pre-disposal processing represents another significant advancement. Modern facilities increasingly incorporate material recovery operations, organic waste diversion systems, and waste-to-energy technologies that modify incoming waste streams before landfill placement. These upstream processes can significantly alter waste characteristics, often resulting in more homogeneous materials with improved compaction properties and reduced environmental impacts. The ramp method's adaptability makes it particularly compatible with these integrated approaches, accommodating changing waste compositions while maintaining operational efficiency.

Technology Enhancements for Modern Ramp Systems

Digitalization has transformed ramp method implementation through comprehensive landfill management software that integrates waste tracking, density monitoring, equipment positioning, and environmental compliance into unified operational platforms. These systems provide real-time visualization of working face conditions, automated reporting for regulatory compliance, and predictive modeling capabilities that optimize daily operations while supporting long-term planning. When combined with machine telematics and automated survey technologies, these digital tools create unprecedented operational visibility and control capabilities.

Integration with Resource Recovery Operations

Forward-thinking facilities now approach landfill operations as one component within integrated resource management systems rather than standalone disposal sites. This perspective recognizes landfills as material reservoirs that may serve future recovery needs while fulfilling immediate disposal requirements. Under this approach, the ramp method's organized filling sequence creates documented material placement zones that could support future mining or resource extraction as technologies and market conditions evolve, preserving long-term recovery options while meeting current disposal needs.

Landfill gas-to-energy systems represent the most widely implemented resource recovery technology, with thousands of facilities worldwide capturing methane for beneficial use. The ramp method's systematic development pattern creates ideal conditions for progressive gas collection system installation, allowing energy recovery to begin early in the site's operational life rather than waiting until closure. This early implementation maximizes energy production potential while significantly reducing the facility's greenhouse gas emissions profile.

Leachate recirculation and bioreactor operations represent more advanced integration approaches that accelerate waste stabilization while potentially increasing gas production rates. The ramp method's controlled filling sequence provides ideal conditions for implementing these techniques, with carefully documented waste placement and comprehensive monitoring systems supporting safe, effective moisture management throughout the waste mass. When properly implemented, these integrated approaches can reduce post-closure care periods while maximizing resource recovery during the landfill's active life. For more insights on landfill operations, explore the comparison between bulldozers and landfill compactors.

Frequently Asked Questions

The following questions address common inquiries about ramp method implementation, operation, and management. While general guidance is provided, specific applications should always consider local regulatory requirements, site conditions, and operational objectives unique to each facility.

What equipment is needed to implement the ramp method?

The essential equipment suite for ramp method operations includes waste placement, compaction, and cover material management machinery. Most facilities operate with at least one track-type dozer (D6 size or larger) for waste spreading and slope creation, a purpose-built landfill compactor (minimum 45,000 pounds) for achieving proper waste density, and an excavator or wheel loader for cover material handling and application. This core equipment set provides the fundamental capabilities needed for effective implementation at small to medium-sized facilities.

Larger operations typically expand this equipment roster to include multiple compactors working in tandem, several dozers assigned to specific functions (waste placement, cover handling, road maintenance), and specialized support equipment including water trucks, motor graders, articulated haul trucks, and tarp deployment systems. This expanded fleet increases processing capacity while providing operational redundancy that ensures continuity even during maintenance activities or equipment breakdowns. For more on equipment specifics, explore the differences between bulldozers and landfill compactors.

Beyond heavy equipment, successful implementation requires appropriate support technologies including communications systems, environmental monitoring tools, survey equipment, and safety devices. Modern operations increasingly incorporate GPS-based machine control systems that provide real-time positioning data, helping operators maintain proper slopes, elevations, and compaction patterns without physical benchmarks or constant surveying.

Equipment selection should consider not just current needs but anticipated future requirements as the facility develops. Machines with adaptable configurations, attachment compatibility, and upgrade potential provide valuable flexibility as operational practices evolve and regulatory requirements change. This forward-looking acquisition strategy maximizes equipment service life while ensuring capabilities remain aligned with operational needs throughout the facility's development. For example, understanding the differences between bulldozers and landfill compactors can help in making informed decisions about equipment selection.

- Track-type dozer (D6 or larger) with waste handling blade

- Purpose-built landfill compactor (minimum 45,000 pounds)

- Excavator or wheel loader for cover material handling

- Water truck for dust suppression and fire control

- Motor grader for access road maintenance

- Support vehicles for personnel transportation and monitoring

How does the ramp method compare to the trench method in terms of cost?

Cost comparisons between landfill methods must consider both initial development expenses and ongoing operational requirements. The ramp method typically demonstrates significant cost advantages in initial development, requiring minimal excavation compared to the extensive earthwork needed for trench method implementation. This difference can represent savings of $250,000 to $1,000,000 per acre in site preparation costs depending on soil conditions, excavation depth requirements, and groundwater management needs. These initial savings must be balanced against potentially higher costs for final cover materials when the facility reaches capacity, as the ramp method generally creates more surface area requiring closure systems.

Operational cost comparisons generally favor the ramp method through reduced equipment hours, lower fuel consumption, and decreased maintenance expenses. The concentrated working area reduces travel distances between active operations, improving productivity while decreasing wear on machine components. Daily cover requirements often decrease as well, particularly when alternative cover systems are implemented, conserving both material resources and valuable airspace that would otherwise be consumed by soil.

| Cost Factor | Ramp Method | Trench Method |

|---|---|---|

| Initial Site Preparation | $50,000-$150,000 per acre | $300,000-$1,200,000 per acre |

| Daily Cover Material | 12-15% of airspace consumption | 15-20% of airspace consumption |

| Equipment Operating Costs | $375-$450 per operating hour | $425-$550 per operating hour |

| Labor Requirements | 4-6 staff for 250 TPD operation | 6-8 staff for 250 TPD operation |

| Final Closure Costs | $200,000-$300,000 per acre | $150,000-$250,000 per acre |

Lifecycle cost analysis typically demonstrates 15-30% overall savings for ramp method operations compared to trench approaches when considering all factors from initial development through post-closure care. These savings become particularly significant for facilities with longer operational lifespans, as the cumulative effect of daily operational efficiencies compounds over time. The financial advantages increase further when considering the opportunity cost of airspace conservation, which effectively extends the facility's revenue-generating capacity without requiring additional permitted area.

It's worth noting that hybrid approaches combining elements of multiple methods often yield optimized results for specific site conditions. For example, initial development might employ trench techniques in appropriate areas to generate cover material stockpiles, transitioning to ramp operations for the majority of the site's active life. This combined approach leverages the strengths of each method while mitigating their respective limitations, potentially delivering superior financial performance compared to strict adherence to any single technique.

Can the ramp method be used in all weather conditions?

The ramp method demonstrates superior all-weather performance compared to many alternative approaches, but does require specific adaptations for extreme conditions. During heavy precipitation, the elevated working face and sloped design naturally shed water away from active operations, maintaining accessibility when flat-surface or excavated disposal areas might become saturated and unworkable. This natural drainage can be enhanced through temporary berms, diversion channels, and strategically positioned pumping systems that manage stormwater without disrupting waste placement activities.

Cold weather operations benefit from the ramp method's flexibility in working face orientation. During winter months, positioning the active area to maximize solar exposure increases surface temperatures, reducing problems with frozen waste and cover materials while improving equipment performance and operator comfort. Snow management becomes simpler as well, with cleared material easily pushed downslope away from active operations rather than creating obstructive berms that interfere with traffic patterns and waste placement. These advantages make the ramp method particularly valuable in northern climates where winter conditions might otherwise significantly impact operational efficiency.

What is the typical lifespan of a ramp method landfill?

Landfill lifespan depends primarily on permitted capacity, waste receipt volumes, and achieved compaction density rather than the disposal method employed. However, the ramp method typically extends operational life by achieving higher waste densities (1,200-1,400 pounds per cubic yard) and maximizing airspace utilization through efficient placement techniques. These factors can increase effective capacity by 10-20% compared to less structured approaches, potentially adding years of operational life without expanding the facility's physical footprint. For a typical medium-sized municipal landfill receiving 250 tons daily, this efficiency improvement might extend operational life from 20 years to 23-24 years within the same permitted volume.

Are there any special permits required for ramp method landfills?

The ramp method does not typically require special permits beyond those mandated for any sanitary landfill operation, as the technique represents an operational approach rather than a fundamentally different facility type. Regulatory requirements generally focus on environmental protection outcomes—including groundwater monitoring, gas management, leachate control, and final closure standards—rather than specifying particular operational methods. This performance-based regulatory approach allows operators to implement the most appropriate techniques for their specific conditions while ensuring consistent environmental protection regardless of the disposal method selected.

Design documentation submitted during the permitting process should clearly describe the planned operational approach, including typical working face dimensions, slope specifications, and phasing sequences that demonstrate how the ramp method will be implemented. Some jurisdictions may require demonstration of slope stability through geotechnical analysis, particularly for facilities planning steeper working faces or those operating in seismically active regions. For more detailed guidelines, refer to this guidebook on landfill plan design. However, these requirements typically apply to any landfill design regardless of the specific operational methodology.

Operational permits sometimes include specific conditions related to working face management, including maximum exposed area limitations, daily cover requirements, and stormwater control provisions. While these conditions might influence how the ramp method is implemented, they rarely prohibit its use when properly designed and operated. In fact, many regulatory agencies favorably view the ramp method's structured approach and concentrated working area as beneficial for environmental control and monitoring purposes.

When transitioning an existing facility from another disposal technique to the ramp method, a permit modification might be required to update operational plans and procedures. These modifications typically undergo less rigorous review than new facility applications, focusing primarily on demonstrating equivalent or improved environmental protection under the revised approach. Operators should consult with regulatory authorities early in the planning process to identify specific requirements and streamline the approval timeline.

Revolutionizing Waste Recovery: Latest Separation And Sorting Innovations

Waste recovery is changing fast, thanks to new separation and sorting technology. This tech helps us sort trash better, so we can recycle more things. For example, Stadler has built a big plant in Spain for VAERSA that makes recycling easier and smarter. Keson is finding new ways to deal with old tyres, helping both […]

Top 10 UK Solid Waste Management Companies 2025

The UK waste management sector stands as a vital industry worth billions of pounds. The top UK Solid Waste Management Companies are the leading waste management firms in Britain. These companies handle millions of tonnes of rubbish each year. The industry has transformed significantly over the past two decades through strategic mergers and environmental innovations. […]

Inert Waste Acceptance Criteria

Inert Waste Disposal and the Requirements for Acceptance Testing The definition of inert waste in the UK, is very restricted by the waste regulations to ensure that when inert waste is disposed to land it will not produce pollution as contaminated groundwater or polluted run-off. This is important as substantial volumes of inert waste remain which […]

Bulldozers Vs Landfill Compactors For The Best Waste Compaction Density

Managing waste at landfills needs proper compaction. Many waste managers struggle to pick between bulldozers and landfill compactors for this job. However, an experienced landfill operator knows that these machines are used best to serve different roles in waste management. Read on because choosing the wrong machine can lead to wasted void space and higher […]