In this article we explain How to Create Site Waste Management Plans (SWMPs) in Easy Steps.

For the contractor this is not “just another chore” to add to the list of record keeping duties.

So what will principal contractors get out of this?

Surprisingly, quite a lot! This is the message according to the research on the actual findings of the voluntary users of SWMPs.

The early adopters of SWMPs found that by placing additional thought and energy into assessing their waste arisings from each project, they could save money. These savings occur when re-using, minimising, and even innovating new uses for their project generated waste. Through SWMPs it has been possible to reduce disposal, and make significant savings in costs.

For contracts valued at above £250,000 these benefits were found to easily exceed the cost of producing and maintaining the SWMP.

How to Create and Implement an SWMP in 9 Easy Steps

We have compiled a 3.5 minute video (also available on YouTube), which you should watch by clicking on the image below. It explains the ‘9 Easy Steps to Prepare a SWMP’. We recommend that you watch it now.

This article was originally created about “How to Comply with the Site Waste Management Plan” requirements in the UK when for a period after their introduction they were a legal requirement, for all large construction sites.

Production of SWMPs, in the UK is purely voluntary.

Nevertheless, anyone who is planning a construction project is well-advised to go through the following steps:

Just to be clear who needs to produce and maintain the SWMP is not something I am going to discuss. It is explained on the official web sites.

Now here is the step by step guidance based upon guidance issued originally by DTI (now BERR).

Step 1 – Identify who is responsible for producing the SWMP and ensuring that it is followed.

Every SWMP should include details of the person who drafted it, the person in charge of the project and (if one has been appointed) the contractor's identity.

If there is more than one contractor, details of the principal contractor should be included.

Keep the SWMP is either in the site office or, if there is no site office, on site.

The reasons for this is that it can be referred to by the site staff, implemented and updated when site circumstances change.

Step 2 – Identify the different types and quantities of waste that will be produced by the project at all stages.

Step 3 – Choose from the waste management options available and note any changes in the design and materials specification that seek to minimize this waste.

Step 4 – Consider how to re-use, recycle or recover the different wastes produced by the project.

Step 5 – Make a check-list of waste management sites and contractors for all wastes that require the companies to demonstrate that they are complying with the Duty of Care regime and recording the quantities of waste transported from site for disposal.

Step 6 – Implement and carry out any necessary training of internal and external staff to ensure that everyone understands the requirements of the SWMP.

Step 7 – Plan for efficient materials and waste handling, and do this early enough bearing in mind any constraints imposed by the site and its location.

The Solid Waste Management Plan must also describe the construction techniques used on the site and its location.

It should also describe:

- the construction works proposed, including the location of the site and estimated value, and

- record decisions made before the SWMP was drafted on the nature of the project, its design, construction method or materials employed.

Step 8 – Measure the quantity and type of waste produced comparing these against the SWMP to ensure that the wastes are properly managed and lessons learned for next time a SWMP is produced.

All figures should be recorded on the datasheet. Every time waste is removed from the site the SWMP must be updated with further information, including:

All figures should be recorded on the datasheet. Every time waste is removed from the site the SWMP must be updated with further information, including:

- type of waste removed

- destination site

- identity of the waste management contractor removing the waste.

The principal contractor should, soon after completion, record on the SWMP a statement confirming that the plan has been monitored on a regular basis to

ensure that work has progressed in accordance with the plan.

Step 9 – Monitor the implementation of the SWMP to ensure that it is being followed and be prepared to update plans if circumstances change. And as part of the process, don't forget to review success of the SWMP at the end of the project, identifying learning points for future reference.

These steps are not a legal requirement, but it makes sense to do them all. The results of so many contractors in the past have been profitable.

Background History to Construction Site Waste Management Plans (SWMPs)

SWMPs were originally compulsory (in England only) and were introduced, in April 2008, by the UK government. As part of simplifying government regulation statutory enforcement, this has changed. Refer to UK government websites for up to date details on that aspect, however, this article still remains relevant otherwise. (Autumn 2014 update.)

When these plans were brought in it was hoped that they would will assist the government in its determination to find ways to control the scourge of fly-tipping.

The regulation which made them compulsory was to mean that SWMPs would have to be produced as evidence that the waste producer, in this case normally the principal contractor, was compliant with their duty of care.

The Waste Duty of Care, was thought to be enough to ensure proper responsible disposal of the materials leaving construction sites under their control. Experience has shown that for the intentionally dishonest fly-tipper, this was not a significant deterrent.e.

If you would like information about:-

a) assistance with SWMP training for your company,

OR

b) assistance with writing your Construction Site Waste Management Plans

from waste management experts who are highly experienced in waste minimisation, re-use, and recycling, and in the aspects of the UK waste management legislation and issues such as:-

- when is a material a waste under the regulations

- what comprises hazardous waste/special waste etc,

then do contact me via the contact page here, and I will put you in touch with experienced experts.

Construction Site waste Management Resources

Waste Managers, Site Managers and Environmental Managers will understand exactly what waste materials are being generated from project level, up through the corporate hierarchy to overall company level. With the information provided by SmartWaste these can then be targeted and reduced, resulting in environmental benefits as well as major cost savings.

Duty of Care Waste Regulations

Waste Management is ideal for maximising reuse and recycling of waste materials on site, as well as improving a company’s overall recycling rate and the diversion of waste from landfill. It also provides a comprehensive platform for managing compliance with Duty of Care waste regulations. This ensures that all necessary evidence of waste carrier licences and environmental permits for waste facilities are in place and stored electronically for easy retrieval. via www.bresmartsite.com

In recent years, construction industry awareness of disposal and reuse issues has been recognized to reduce volumes of construction and demolition waste disposed in landfills.

Beneficial Reduction and Recovery of Materials Through Using Site Waste Management Plans

Many opportunities exist for the beneficial reduction and recovery of materials that would otherwise be destined for disposal as waste.

Construction industry professionals and building owners can educate and be educated about issues such as beneficial reuse. Effective strategies should be devised for identification and separation of wastes. Economically viable means of promoting environmentally and socially appropriate means of reducing total waste disposed should also be considered.

Organizations and governments can assume stewardship responsibilities for the orderly, reasonable, and effective disposal of building-related waste.

Plus, promotion of public and industry awareness of disposal issues. Also, it is important to provide stable business-friendly environments for collecting, processing, and repurposing of wastes.

Businesses can create value through the return of wastes back to manufacturing processes. This is done by promoting and seeking out opportunities for incorporation of recycled materials into products.

All this should end-up by prioritizing reduction of building-related wastes through efficient jobsite practices. via www.wbdg.org

Safety Considerations for Good SWMPs

However, all waste produced can also present a real safety hazard to workers on site. This occurs if waste it is not properly managed throughout the project.

How wastes streams produced during building work need to be managed in a timely and effective way.

Plus, “Who” – is responsible for collecting and disposal of specific wastes produced on site. Problems often arise when company and individual duties are not made clear before work starts.

Flammable materials

Make sure that all flammable waste materials are cleared away regularly to reduce fire risks. Examples are packaging and timber off-cuts.

Work areas

Make clearing waste in work areas a priority for all trades. Check that everyone is aware of what is required that it is being done.

Skips

Waste materials need storing safely before their removal from the site. Make sure that you allow sufficient space for waste skips and bins etc.

Plan where the skips can be positioned and how often they will need to be collected.

Waste within buildings

Consider waste generated inside buildings and whether you need to provide wheeled bins or chutes etc. via www.hse.gov.uk

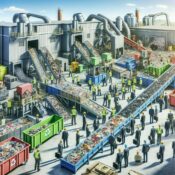

Revolutionizing Waste Recovery: Latest Separation And Sorting Innovations

Waste recovery is changing fast, thanks to new separation and sorting technology. This tech helps us sort trash better, so we can recycle more things. For example, Stadler has built a big plant in Spain for VAERSA that makes recycling easier and smarter. Keson is finding new ways to deal with old tyres, helping both […]

Top 10 UK Solid Waste Management Companies 2025

The UK waste management sector stands as a vital industry worth billions of pounds. The top UK Solid Waste Management Companies are the leading waste management firms in Britain. These companies handle millions of tonnes of rubbish each year. The industry has transformed significantly over the past two decades through strategic mergers and environmental innovations. […]

Ramp Method of Waste Disposal – Landfill Guide & Techniques

The ramp method optimizes landfill operations by creating an inclined surface, allowing efficient waste compaction and daily cover application. Unlike traditional methods, it requires minimal excavation, reducing costs and extending landfill lifespan. Proper implementation and equipment maintenance are key to effective ramp method performance in various terrains…

The Future of UK Food Waste Management – Simpler Collections and Tougher Regulation

The future of UK food waste management will be a big push toward higher recycling rates through simpler collection and far greater consistency across the nations, helping citizens understand how to be green and recycle more organic waste. As the UK continues to advance its environmental goals, recently announced government policies aimed at simplifying waste […]